|

item

|

valve

|

|

Application

|

Industry, Power Plant, Marine, Oil

|

|

Port Size

|

DN15-DN150

|

|

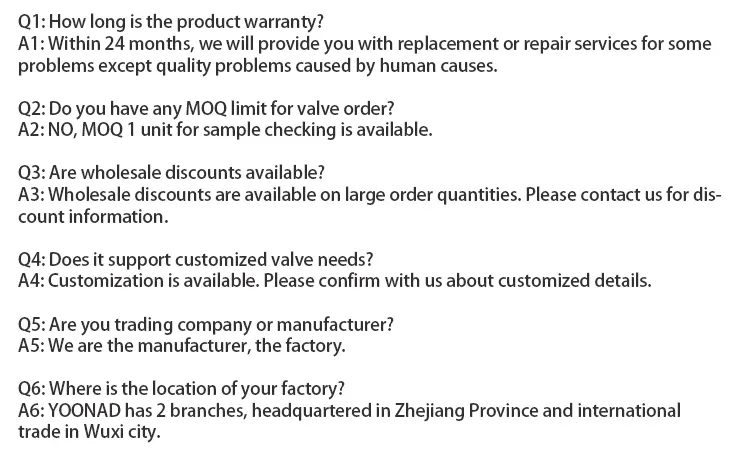

Warranty

|

2 Years

|

|

Place of Origin

|

China

|

|

Zhejiang

|

|

|

Model Number

|

BVC004

|

|

Power

|

Manual, Electric, Pneumatic, Hydraulic

|

|

Temperature of Media

|

High Temperature, Low Temperature, Medium Temperature, Normal Temperature

|

|

Structure

|

Floating, Trunnion

|

|

Media

|

Oil, Water, Steam, LNG, LOX

|

|

Customized support

|

OEM, ODM, OBM

|

Stainless Steel Ball Valve

The stainless steel ball valve only needs to be rotated 90 degrees and the torque is small to close tightly. The completely equal body cavity provides a straight-through flow path with minimal resistance to the medium. The main feature of the ball valve is that it is compact in structure, easy to operate and maintain, stainless steel ball valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media.

The fluid resistance is small, and its resistance coefficient is equal to that of a pipe section of the same length.

Simple structure, small size and light weight.

Tight and reliable, the sealing surface material of the ball valve is widely used plastic, good sealing, and the working principle of stainless steel ball valve has also been widely used in the vacuum system.

Easy to operate, quick to open and close, and only needs to rotate 90°from full open to full closeed, which is convient for

long-distance control.

Easy to maintain, the sealing ring is generally movable, and it is more convenient to disassemble and replace.

When fully open or fully closed, the sealing surface of the ball and valve seat is isolated from the medium, and when the medium passes, it will not cause erosion of the sealing surface of the valve.

It can be used in a wide range of applications, from small to a few millimeters and several meters in diameter, from high vacuum to high pressure.

Simple structure, small size and light weight.

Tight and reliable, the sealing surface material of the ball valve is widely used plastic, good sealing, and the working principle of stainless steel ball valve has also been widely used in the vacuum system.

Easy to operate, quick to open and close, and only needs to rotate 90°from full open to full closeed, which is convient for

long-distance control.

Easy to maintain, the sealing ring is generally movable, and it is more convenient to disassemble and replace.

When fully open or fully closed, the sealing surface of the ball and valve seat is isolated from the medium, and when the medium passes, it will not cause erosion of the sealing surface of the valve.

It can be used in a wide range of applications, from small to a few millimeters and several meters in diameter, from high vacuum to high pressure.

The ball valve operates by rotating the ball 90 degrees using a handle or actuator, which changes the alignment of the hole or passage. When the hole aligns with the inlet and outlet ports, the valve is open, allowing the fluid or gas to flow through. When the hole is perpendicular to the ports, the valve is closed, stopping the flow.

High pressure industrial ball valves are specifically designed to withstand and regulate the flow of fluids or gases under high pressure conditions, typically ranging from a few hundred to several thousand pounds per square inch (psi). These valves are constructed using robust materials such as stainless steel, carbon steel, or other alloys that can handle the high pressures without leaking or failing.

High pressure industrial ball valves are specifically designed to withstand and regulate the flow of fluids or gases under high pressure conditions, typically ranging from a few hundred to several thousand pounds per square inch (psi). These valves are constructed using robust materials such as stainless steel, carbon steel, or other alloys that can handle the high pressures without leaking or failing.

They are commonly used in various industries such as oil and gas, petrochemical, power generation, chemical processing, and water treatment, where reliable control of high-pressure fluids or gases is required. High pressure ball valves offer several advantages, including quick and easy operation, excellent sealing capabilities, minimal pressure drop, and durability in demanding environments.

Technical Specification

1. Design & Manufacture standard: GB/T-12237

2. Pressure & Temperature standard: GB/T13927-2008

3. Face-to-face dimension standard: GB/T-12221,JB/T-1686

4. Flange standard: GB/T-2592,JB/T-79.15. Test & Inspect stand: GB/T-13927,JB/T-9092

Technical Specification

1. Design & Manufacture standard: GB/T-12237

2. Pressure & Temperature standard: GB/T13927-2008

3. Face-to-face dimension standard: GB/T-12221,JB/T-1686

4. Flange standard: GB/T-2592,JB/T-79.15. Test & Inspect stand: GB/T-13927,JB/T-9092

1.6Mpa Dimension:

|

type

|

DN(mm)

|

Dimension(mm)

|

||||||||||||||

|

L

|

D

|

D1

|

D2

|

b-f

|

z-Φd

|

H

|

W

|

|||||||||

|

Q41F-16C Q341F-16C Q641F-16C Q941F-16C

|

15

|

130

|

95

|

65

|

45

|

14-2

|

4-Φ14

|

65

|

115

|

|||||||

|

20

|

140

|

105

|

75

|

55

|

14-2

|

4-Φ14

|

75

|

130

|

||||||||

|

25

|

150

|

115

|

85

|

65

|

14-2

|

4-Φ14

|

85

|

150

|

||||||||

|

32

|

165

|

135

|

100

|

78

|

16-2

|

4-Φ18

|

95

|

190

|

||||||||

|

40

|

180

|

145

|

110

|

85

|

16-3

|

4-Φ18

|

105

|

230

|

||||||||

|

50

|

200

|

160

|

125

|

100

|

16-3

|

4-Φ18

|

115

|

240

|

||||||||

|

65

|

220

|

180

|

145

|

120

|

18-3

|

4-Φ18

|

145

|

280

|

||||||||

|

80

|

250

|

195

|

160

|

135

|

20-3

|

8-Φ18

|

160

|

310

|

||||||||

|

100

|

280

|

215

|

180

|

155

|

20-3

|

8-Φ18

|

185

|

330

|

||||||||

|

125

|

320

|

245

|

210

|

185

|

22-3

|

8-Φ18

|

215

|

600

|

||||||||

|

150

|

360

|

280

|

240

|

210

|

24-3

|

8-Φ23

|

245

|

800

|

||||||||

|

200

|

400

|

335

|

295

|

265

|

26-3

|

12-Φ23

|

300

|

1000

|

||||||||

|

250

|

450

|

405

|

355

|

320

|

30-3

|

12-Φ25

|

380

|

1200

|

||||||||

2.5MPa Dimension:

|

type

|

DN(mm)

|

(mm)

|

||||||||||||||

|

L

|

D

|

D1

|

D2

|

b-f

|

z-Φd

|

H

|

W

|

|||||||||

|

Q41F-25C

Q341F-25C

Q641F-25C

Q941F-25C

|

15

|

130

|

95

|

65

|

45

|

14-2

|

4-Φ14

|

65

|

115

|

|||||||

|

20

|

140

|

105

|

75

|

55

|

14-2

|

4-Φ14

|

75

|

130

|

||||||||

|

25

|

150

|

115

|

85

|

65

|

14-2

|

4-Φ14

|

85

|

150

|

||||||||

|

32

|

165

|

135

|

100

|

78

|

16-2

|

4-Φ18

|

95

|

190

|

||||||||

|

40

|

180

|

145

|

110

|

85

|

18-3

|

4-Φ18

|

105

|

230

|

||||||||

|

50

|

200

|

160

|

125

|

100

|

20-3

|

4-Φ18

|

115

|

240

|

||||||||

|

65

|

220

|

180

|

145

|

120

|

22-3

|

8-Φ18

|

145

|

280

|

||||||||

|

80

|

250

|

195

|

160

|

135

|

22-3

|

8-Φ18

|

160

|

310

|

||||||||

|

100

|

280

|

230

|

190

|

160

|

24-3

|

8-Φ23

|

185

|

330

|

||||||||

|

125

|

320

|

270

|

220

|

188

|

28-3

|

8-Φ25

|

215

|

600

|

||||||||

|

150

|

360

|

300

|

250

|

218

|

30-3

|

8-Φ25

|

245

|

800

|

||||||||

|

200

|

400

|

360

|

310

|

278

|

34-3

|

12-Φ25

|

300

|

1000

|

||||||||

|

250

|

450

|

425

|

370

|

332

|

36-3

|

12-Φ30

|

380

|

1200

|

||||||||

Reviews

There are no reviews yet.