Why Choose Us

|

27 years

experience in rubber production

|

360+

employees

|

71,000 m²

factory area

|

5

large-scale production workshops

|

125 million

registered capital (fully paid-in)

|

|

20+

self-developed patents

|

200+

production equipment

|

10,000+

existing product types

|

1,000+ tons

monthly production capacity

|

30+

designers

|

|

10+

research and development teams

|

50+

system certifications/certificates

|

30+

cooperative countries

|

10+

vulcanization production lines

|

20,000 m²

warehouse area

|

My business partner

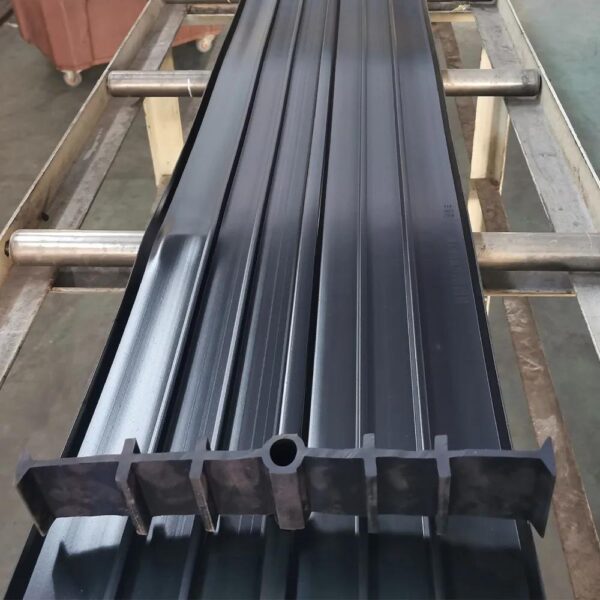

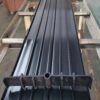

Products Description

Rubber waterstop including: water stop body (1); the water stop (1) to open the projection (2); open recess in the back of the projection (2) (3), the surface water stop body (1) opened jagged lines, forming a seal line (5). The utility model elastic rubber water-stop structure formed by projections and recesses involved sufficiently superior gap filling sealing structure of the sealing performance, practical. Our independent research extruded EPDM rubber water-stop material, preferably its anti-aging properties and low temperature performance, advanced products belong

back mounted rubber waterstop,

Back mounted rubber waterstop, is also called back type water stop belt or external water stop belt, is the 1 kind of underground structures in the concrete deformation joint, settlement joint wall plate outside (water surface) set up the 1 kind of water stop structure, with the material elasticity and structure of the water stop belt to adapt to the expansion and deformation of concrete.

middle buried rubber waterstop

Middle buried rubber waterstop ,which is the 1 kind of water stop belt products mainly used in concrete deformation joints, expansion joints and other concrete internal settings, with rubber material elasticity and structural form to adapt to the ability of concrete expansion and deformation.

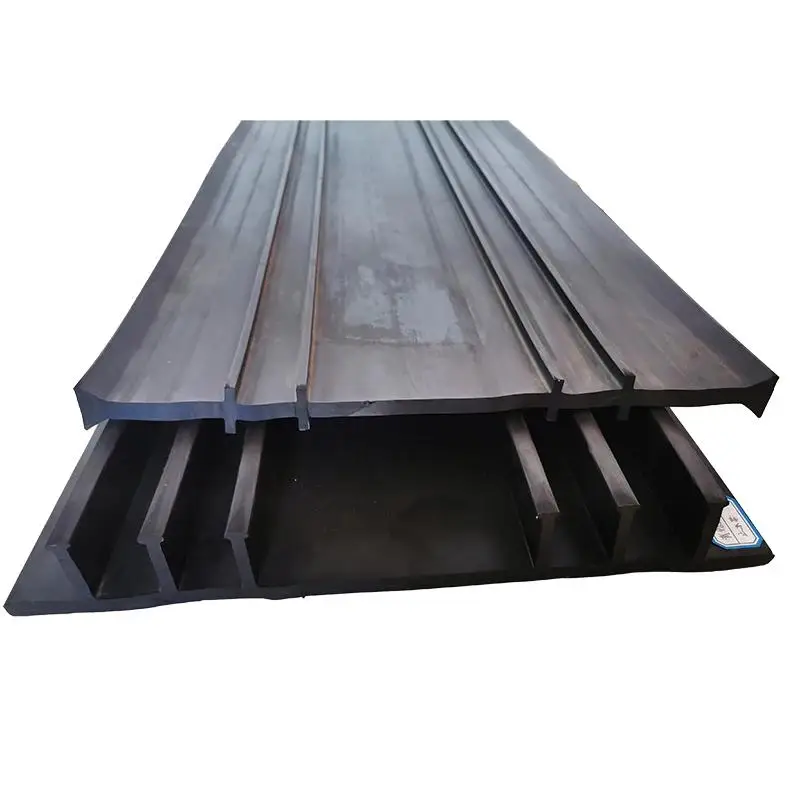

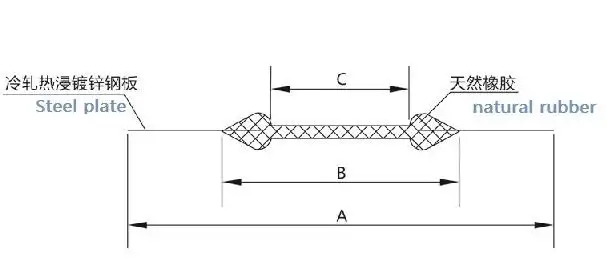

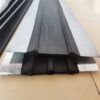

Steel edge type rubber waterstop

Steel edge water stop belt (also known as: steel edge rubber water stop belt) is the rubber water stop belt section adopts non equal thickness structure, divided into strong area and waterproof area, so that each part of the force is uniform and reasonable. In the steel plate of the water stop, the installation hole is connected with the steel bar, which is fixed firmly and not easy to be displaced, so that the force of each part is uniform and reasonable. The long wall of the telescopic hole of the steel edge water stop is flat, and the contact surface of the plate mold clamping is large during the construction of the water stop, and it is not easy to displace. The steel plate is connected with the steel bar by adding installation holes, which are firmly fixed and

not easy to displace.

not easy to displace.

Can choose whether to bring adhesive

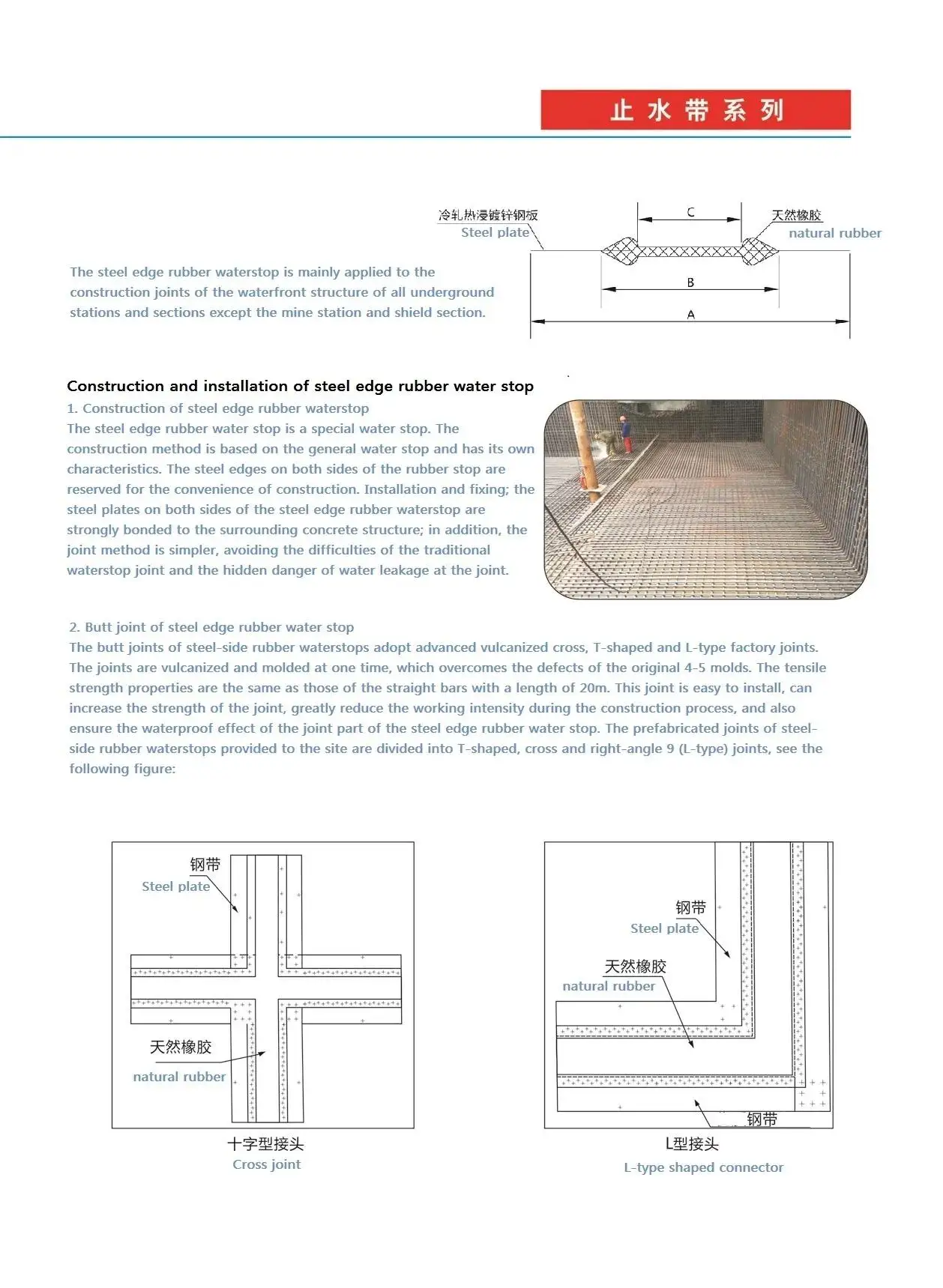

The steel edge rubber waterstop is mainly applied to theconstruction joints of the waterfront structure of all undergroundstations and sections except the mine station and shield section.

construction and installation of steel edge rubber water stop

Construction of steel edge rubber waterstop The steel edge rubber water stop is a special water stop. The construction method is based on the general water stop and has its own characteristics. The steel edges on both sides of the rubber stop areeserved for the convenience of construction. Installation and fixing; the steel plates on both sides of the steel edge rubber waterstop are stronaly bonded to the surrounding concrete structure: in addition. the joint method is simpler, avoiding the difficulties of the traditional waterstop joint and the hidden danger of water leakage at the joint

Butt ioint of steel edae rubber waterstop

The butt joints of steel-side rubber waterstops adopt advanced vulcanized cross, T-shaped and L-type factory joints.The joints are vulcanized and molded at one time, which overcomes the defects of the original 4-5 molds. The tensile strength properties are the same as those of the straight bars with a length of 20m. This joint is easy to install, can increase the strenath of the ioint, greatly reduce the working intensity during the construction process, and also ensure the waterproof effect of the joint part of the steel edge rubberwater stop. The prefabricated ioints of steel-side rubber waterstops provided to the site are divided into T-shaped, cross and right-angle 9 (L-type) joints, see the following figure:

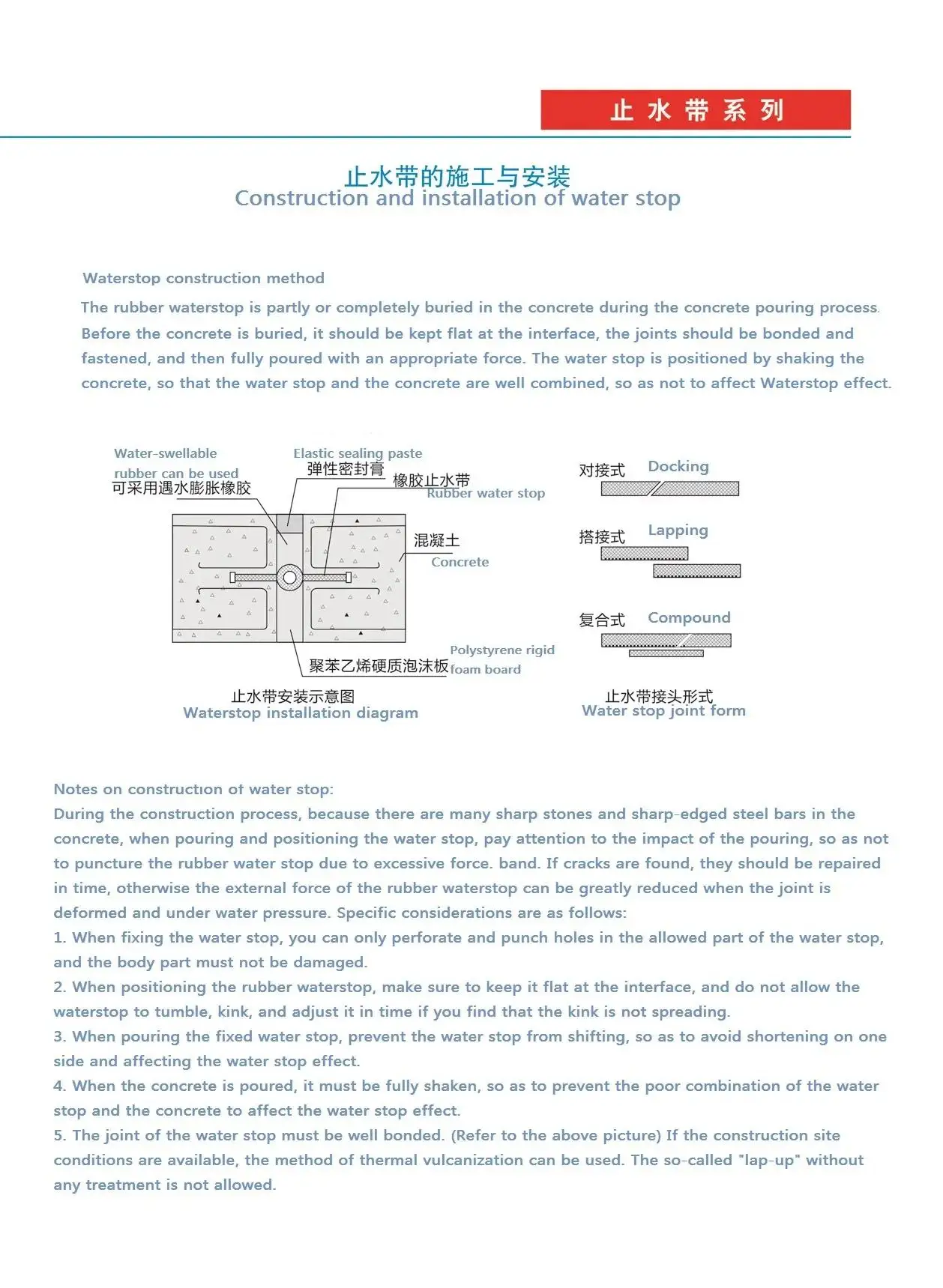

Construction and installation of water stop

Waterstop construction method

The rubber waterstop is partly or completely buried in the concrete during the concrete pouring processBefore the concrete is buried, it should be kept flat at the interface, the joints should be bonded andfastened, and then fully poured with an appropriate force. The water stop is positioned by shaking theconcrete, so that the water stop and the concrete are well combined, so as not to affect Waterstop effect

Notes on construction ot water stop: During the construction process, because there are many sharp stones and sharp-edged steel bars in theconcrete, when pouring and positioning the water stop, pay attention to the impact of the pouring, so as notto puncture the rubber water stop due to excessive force. band. lf cracks are found, they should be repairedin time, otherwise the external force of the rubber waterstop can be greatly reduced when the joint isdeformed and under water pressure.

Specific considerations are as follows:

1. When fixing the water stop, you can only perforate and punch holes in the allowed part of the water stopand the body part must not be damaged

2. When positioning the rubber waterstop, make sure to keep it flat at the interface, and do not allow thewaterstop to tumble, kink, and adjust it in time if you find that the kink is not spreading.

3. When pouring the fixed water stop, prevent the water stop from shifting, so as to avoid shortening on oneside and affecting the water stop effect.

4. When the concrete is poured, it must be fully shaken, so as to prevent the poor combination of the waterstop and the concrete to affect the water stop effect. 5. The joint of the water stop must be well bonded. (Refer to the above picture) If the construction siteconditions are available, the method of thermal vulcanization can be used. The so-called “lap-up” withoutany treatment is not allowed.

Product Application

Specification

|

item

|

value

|

|

Warranty

|

NONE

|

|

After-sale Service

|

Online technical support

|

|

Project Solution Capability

|

total solution for projects

|

|

Application

|

building waterproof

|

|

Design Style

|

Modern

|

|

Place of Origin

|

China

|

|

Hebei

|

|

|

Brand Name

|

Xingyuan

|

|

Model Number

|

Rubber waterstop

|

|

Type

|

Water stop

|

|

Material

|

Rubber

|

|

Shape

|

Surface uneven type

|

|

Core Material

|

Rubber

|

|

Format

|

Microporous

|

|

Product Name

|

rubber waterstop

|

|

Color

|

Black

|

|

Size

|

Accept Customized

|

|

Function

|

Contruction Waterproof

|

|

Advantage

|

Easy Construction

|

|

Main Material

|

Rubber

|

Company Profile

Hebei Xingyuan Sealing Parts Group Co., Ltd. (formerly Hebei Xingyuan Auto Parts Group Co., Ltd.) is located in Qinghe County, Xingtai City, Hebei Province, with railways and high-speed crossings, and the transportation is very convenient. Founded in 1998 with a registered capital of 125 million yuan, the company is an excellent rubber products enterprise integrating R&D, production, sales and service. The company has a professional technical research and development team, and has established a physical and chemical test center, with complete testing methods. The company has 8 functional departments and four comprehensive workshops and equipment power workshops for rubber mixing, extrusion, vulcanization and machining, and has several CNC machining equipment, with special equipment, tooling facilities, and mold independent research and development capabilities.

The company mainly produces EPDM automotive sealing strip series, EPDM elastic sealing gasket for shield segments, rubber waterstop, rubber bearing, construction friction pendulum bearing, rubber overboots and block lower backing plate, elastic backing plate, water-swelling waterproof strip, sealing rubber ring, injection molding series, molding series, etc., covering aviation, trains, railways, subways, tunnels, bridges, buildings , automobiles , ships, building curtain walls, aluminum-plastic doors and windows, electrical cabinets , containers and waterproof buildings and other sealing and shock-absorbing industries, and also provides a variety of technical support, science and technology research and development, sales network throughout the country more than 20 provinces, municipalities and autonomous regions, products are exported to the United States, Canada, Australia, New Zealand and other overseas more than 10 countries and regions.

The company attaches great importance to product quality management, and has successively passed ISO/9001: 2015, IATF16949: 2021, IS014001: 2015, ISO45001: 2018 system certification and SGS, CE certificate, our company adheres to the quality policy of “quality first, reputation first, providing customers with high-quality products and services”.

Why Choose Us

Advanced production equipment

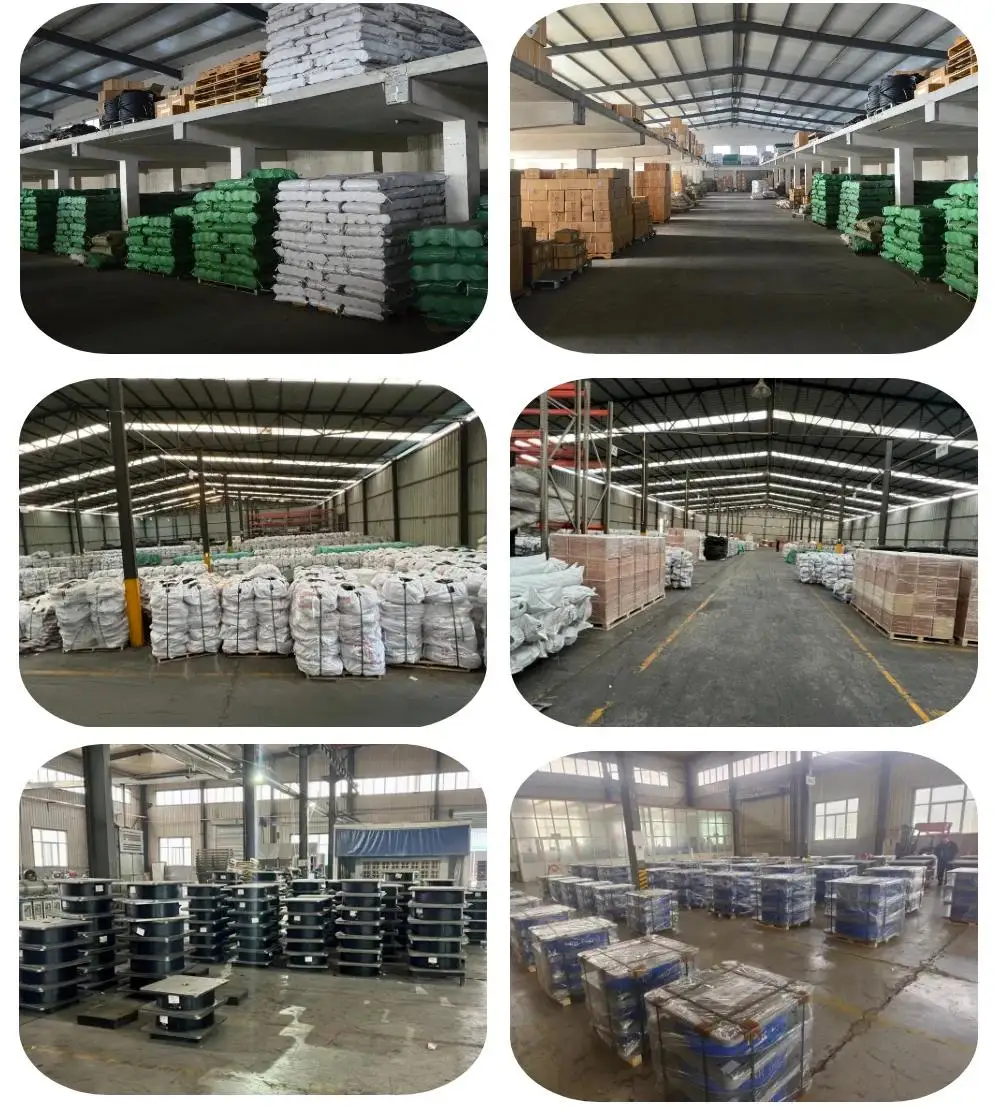

Adequate inventory

praise from customers

Transportation and packaging

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacturer.

A: We are manufacturer.

Q2: What’s your MOQ?

A: Normally it’s 500 meters for one size and one color.

A: Normally it’s 500 meters for one size and one color.

Q3: What’s your output?

A:500,000 meters per week

A:500,000 meters per week

Q4: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. And for mass production it takes 15-20 days.

A: Generally it is 5-10 days if the goods are in stock. And for mass production it takes 15-20 days.

Q5: May I have samples ? is it free or extra?

A: Yes, we are happy to explore new product with our customers. If the sample need to be customized, please contact us. For the regular item, we supply 3-5meters samples for free. And customer pay the sample freight only.

A: Yes, we are happy to explore new product with our customers. If the sample need to be customized, please contact us. For the regular item, we supply 3-5meters samples for free. And customer pay the sample freight only.

Q6: Whether to support customized services?

A:We can customize according to drawings or samples,Production mold independent research and development manufacturing, independent transformation of production equipment.

A:We can customize according to drawings or samples,Production mold independent research and development manufacturing, independent transformation of production equipment.

Q7: What is your terms of delivery?

A:EXW.FOB.CFR.CIF,DDU.etc.

A:EXW.FOB.CFR.CIF,DDU.etc.

Reviews

There are no reviews yet.