Why Choose Us

|

27 years

experience in rubber production

|

360+

employees

|

71,000 m²

factory area

|

5

large-scale production workshops

|

125 million

registered capital (fully paid-in)

|

|

20+

self-developed patents

|

200+

production equipment

|

10,000+

existing product types

|

1,000+ tons

monthly production capacity

|

30+

designers

|

|

10+

research and development teams

|

50+

system certifications/certificates

|

30+

cooperative countries

|

10+

vulcanization production lines

|

20,000 m²

warehouse area

|

My business partner

Products show

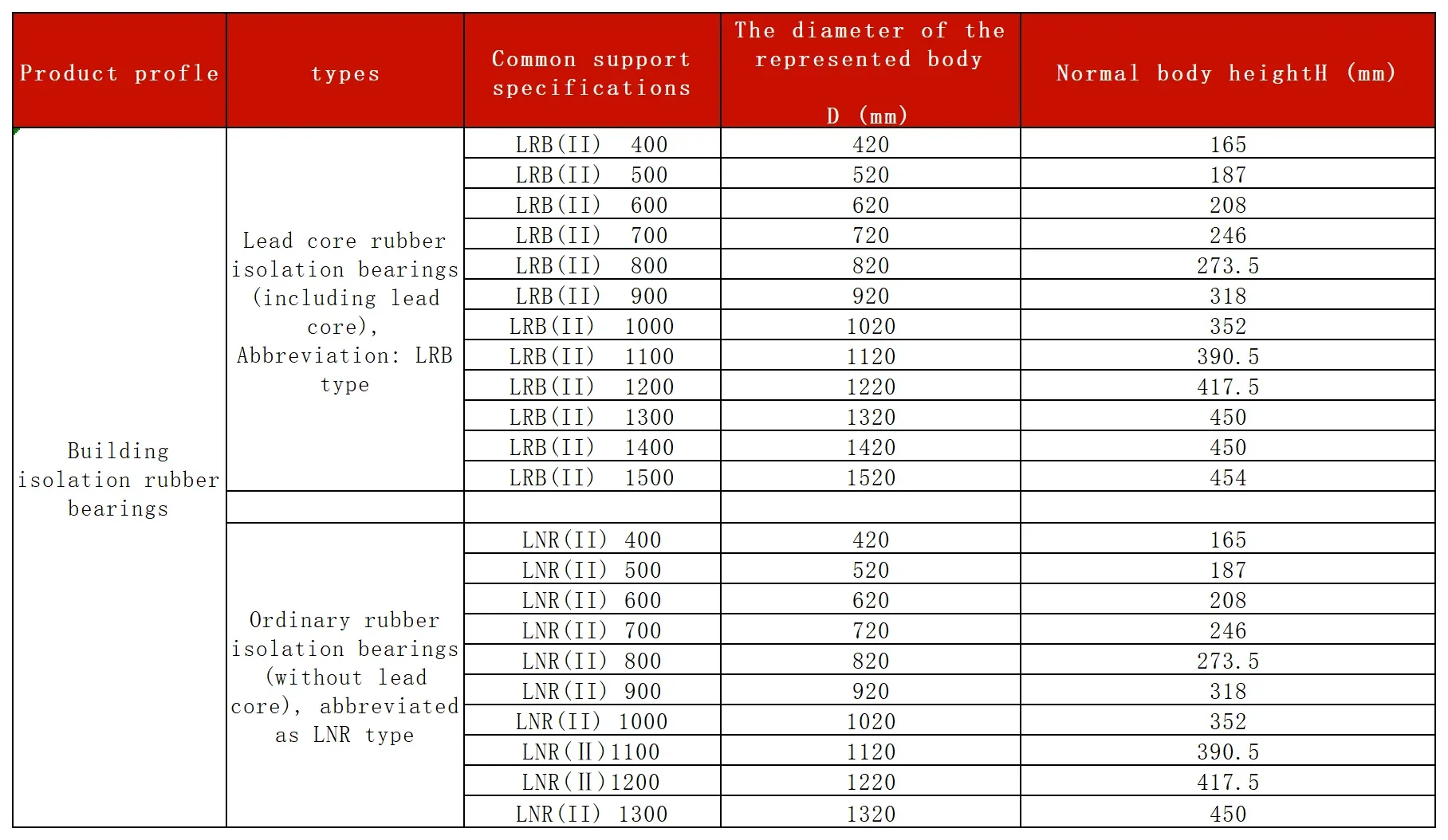

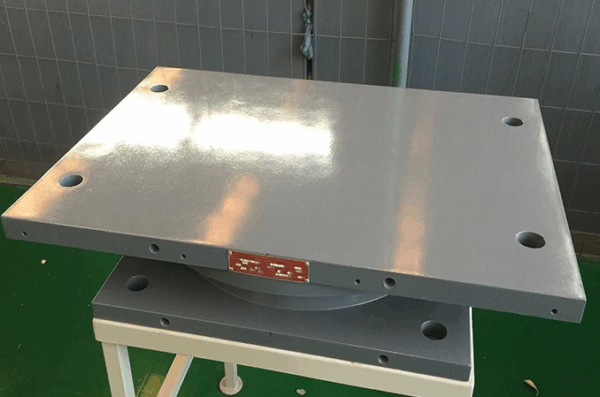

Building isolation rubber bearings

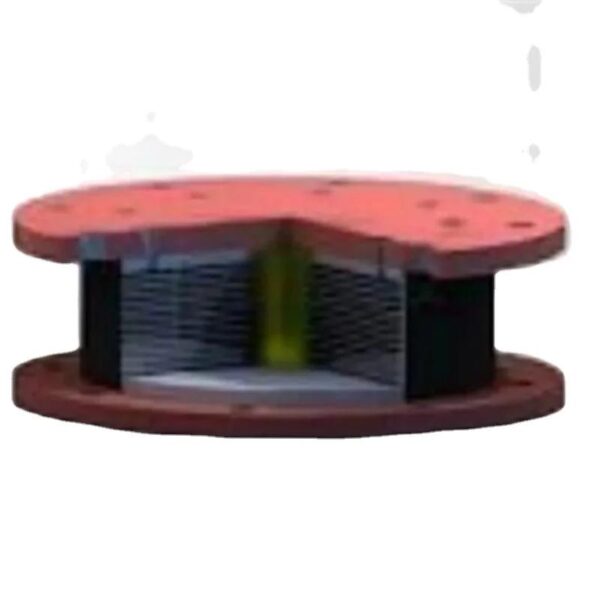

Building isolation rubber bearings are a type of elastic support isolation device, which is composed of alternating thin steel plates and thin rubber plates, and is vulcanized at high temperature and high pressure. Building isolation rubber bearings are a proactive seismic method that uses flexible materials such as rubber to make rubber isolation bearings, which are installed at the bottom or lower part of the building and form a flexible isolation layer between the upper structure to absorb and dissipate seismic energy, reduce the input of seismic energy to the upper structure of the building, and achieve seismic resistance.

Product execution standards

1. GB 20688.3-2006 “Rubber Bearings – Building Seismic Isolation Rubber Bearings”

2. JG 118-2018 “Rubber Bearings for Seismic Isolation in Buildings”

3. DBJ 53/T-47-2020 “Performance requirements and inspection specifications for laminated rubber isolation bearings in building engineering”

4. JGJ 360-2015 “Code for Construction and Acceptance of Building Seismic Isolation Engineering”

Basic Principles

The basic principle of building isolation with rubber bearings is to extend the natural vibration period of the entire building by adding rubber bearings, in order to reduce the seismic response of the upper structure. The general practice is to design a seismic isolation layer at the bottom of the building, install rubber isolation bearings on the isolation layer, and use the horizontal flexibility of the rubber isolation bearings to form a flexible isolation layer. Through the flexible isolation layer, seismic energy is absorbed and dissipated, preventing and reducing the transmission of seismic energy to the upper structure, ultimately achieving the goal of reducing seismic damage to the upper structure. This isolation technology not only ensures the overall safety of the structure, but also prevents damage to non structural components, avoids damage to building interior decoration, indoor equipment, and secondary disasters caused by it.

Application scenarios

hospital

school

research base

bridge

high-speed railway

Mechanical and electrical equipment

Product category image

Product advantages

① Good isolation effect

② Strong load-bearing capacity

③ Good adjustability

④ Convenient construction

⑤ Easy maintenance and management

1. Hardware strength: The company has industry-leading key process production and testing equipment, including an automated rubber mixing processing center, a four roll rolling film production line, a 20000kN support shear testing machine, and rubber full process testing and testing instruments.

2. Production capacity: The company currently has more than 80 vulcanization machines and is capable of producing 400-1600 full specification series isolation bearings (or customized product specifications according to customer requirements), with an annual production capacity of 5000 cubic meters of isolation bearings.

Transportation and packaging

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacturer.

A: We are manufacturer.

Q2: What’s your MOQ?

A: Normally it’s 500 meters for one size and one color.

A: Normally it’s 500 meters for one size and one color.

Q3: What’s your output?

A:500,000 meters per week

A:500,000 meters per week

Q4: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. And for mass production it takes 15-20 days.

A: Generally it is 5-10 days if the goods are in stock. And for mass production it takes 15-20 days.

Q5: May I have samples ? is it free or extra?

A: Yes, we are happy to explore new product with our customers. If the sample need to be customized, please contact us. For the regular item, we supply 3-5meters samples for free. And customer pay the sample freight only.

A: Yes, we are happy to explore new product with our customers. If the sample need to be customized, please contact us. For the regular item, we supply 3-5meters samples for free. And customer pay the sample freight only.

Q6: Whether to support customized services?

A:We can customize according to drawings or samples,Production mold independent research and development manufacturing, independent transformation of production equipment.

A:We can customize according to drawings or samples,Production mold independent research and development manufacturing, independent transformation of production equipment.

Q7: What is your terms of delivery?

A:EXW.FOB.CFR.CIF,DDU.etc.

A:EXW.FOB.CFR.CIF,DDU.etc.

Reviews

There are no reviews yet.