Every year, traffic cones stop many road accidents. They guide cars and keep workers safe. Buyers everywhere should look at things like height, material, and reflectivity. These help make cones easy to see and last longer. Rules like MUTCD and EN 13422 set cone sizes, colors, and retroreflective bands. This keeps roads safe and follows the law. Good suppliers follow these rules. This makes sure every project is safe and legal.

Key Takeaways

- Traffic cones help keep drivers and workers safe. They show where dangers are and help guide cars in roads and events. – Pick cones with the right size, color, and reflective collars. This helps people see them during the day and at night. – PVC, rubber, and PE are materials that change how strong and heavy cones are. Choose the material that fits your weather and job needs. – Always get cones that follow safety rules like MUTCD or EN 13422. Make sure they have the right certificates. – Think about storage, shipping, and if the supplier is reliable. This can help you save money and stop delays when you buy cones.

Definition and History

What Are Traffic Cones

Traffic cones are important for safety on roads and at construction sites. People use them to show where dangers are and to help cars go the right way. They also keep people away from unsafe spots. These cones have a cone shape and a wide base so they do not fall over. Their bright colors, like orange or lime green, help people see them during the day. Many cones have shiny collars that help drivers see them at night or when it is hard to see. Companies make traffic cones light, easy to carry, and strong. This helps workers move them fast when needed.

Tip: Always make sure cones follow safety rules before you buy them for any job.

Brief History

Traffic cones started being used in the early 1900s. At first, people tried using heavy concrete or metal markers. These were hard to move and not safe. In 1943, Charles D. Scanlon from the United States made the first modern traffic cone. He made it out of rubber so it could bend and not break if hit. This new cone helped keep workers and drivers safer.

The table below shows some big moments in the history of traffic cones:

| Event | Date | Location | Description |

|---|---|---|---|

| Invention and patent | 1943 | United States | Charles D. Scanlon patented the first rubber traffic cone. |

| First use in UK | 1958 | United Kingdom | Cones replaced lanterns on the M6 motorway for better visibility. |

| First use in US for worker safety | May 1, 1959 | Oakland, California, USA | Pacific Gas and Electric Company adopted orange cones for safety. |

Over time, traffic cones changed a lot. Makers stopped using rubber and started using plastics like PVC and PE. These new plastics made cones lighter and stronger in the 1960s and 1970s. In the 1980s, cones got colors that did not fade in the sun. By the 1990s, most cones had shiny bands so people could see them at night. Now, some cones even have smart features like sensors and LED lights. These can collect information and warn drivers right away. All these changes help keep roads safe and protect workers.

Traffic Cones: Sizes and Colors

Common Sizes

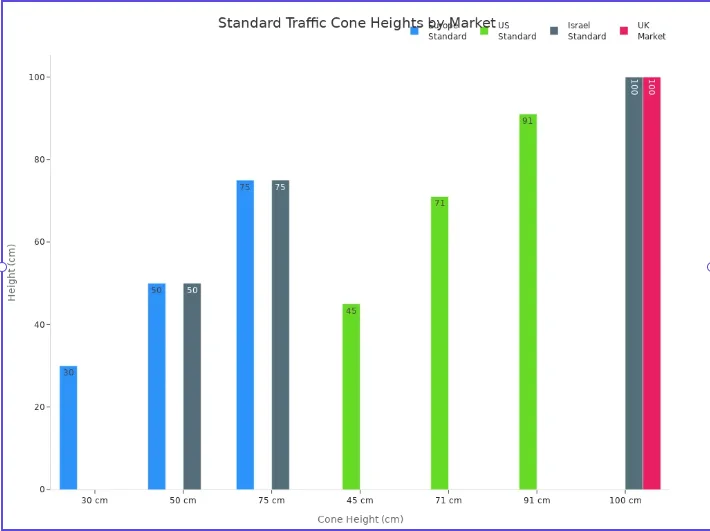

Traffic cones come in many heights for different jobs. In the United States, the most used sizes are 18 inches, 28 inches, and 36 inches. Europe uses cones that are 30 cm, 50 cm, or 75 cm tall. The UK and Israel sometimes use cones as tall as 1 meter. Bigger cones are easier to see, especially on highways or at night. Smaller cones are good for inside or slow traffic areas. In the US, MUTCD rules say cones must be at least 28 inches tall for highways. These cones also need shiny collars for safety at night.

| Market/Standard | Typical Traffic Cone Heights | Base Dimensions (approx.) | Notes |

|---|---|---|---|

| Europe Standard | 30 cm, 50 cm, 75 cm (12″, 20″, 30″) | 22.5×22.5 cm to 39.5×39.5 cm | PVC, flexible, reflective optional |

| US Standard | 18″, 28″, 36″ (45 cm, 71 cm, 91 cm) | 28-36 cm base | Orange PVC, road safety |

| Israel Standard | 50 cm, 75 cm, 100 cm (20″, 30″, 39″) | Not specified | PE cones, Asia region |

| UK Market | 1 meter (39″) | Not specified | Heavy duty PE, highways |

Who we are

Hebei Shangze Rubber & Plastic Products Co., Ltd. is headquartered in Hengshui City, Hebei Province—the core cluster of China’s traffic-safety manufacturing industry. Our self-built, 28,000 m² state-of-the-art production base has been dedicated to the R&D, manufacture and export of all types of traffic cones for 15 years. Certified to ISO 9001, ISO 14001, CE and REACH, we are the long-term partner for municipal roads, highways, airports, seaports and major sports venues in more than 60 countries worldwide.

We have pe material, pvc material and rubber material traffic cones, height we have 45cm, 65cm, 70cm and 90cm, base we have 270*270 , 280*280, 360*360 370*370 and 400*400mm weight we have 4.5kg, 4.2kg and 1.5kg, 1kg, 2.4kg.

We operate an industry-leading, fully modernized production system:Our entire line is equipped with German-imported high-precision injection molding machines, automated robotic pick-and-place systems and constant-temperature, constant-consumption silos that keep melt temperature within ±2 °C, eliminating voids, warpage and other defects.

For every mainstream traffic-cone size on the market—from 300 mm mini cones up to 1 m high-performance units, including foldable, LED-illuminated, solar-powered and ballasted wind-resistant models—we design and machine our own molds. Each mold features interchangeable base plates and reflective-sleeve sliders, allowing a model changeover in only three minutes. This enables flexible, low-volume, rapid-iteration production and fully meets any customer customization requirement.

Color Guide

The color of a traffic cone helps people know what is happening. Orange cones are used most for road work and building sites in the US and India. Lime green cones show places where drivers must pay extra attention, like near schools or service areas. In Germany and the UK, red and white cones warn about dangers or short-term road blocks. Yellow cones are used in snowy places like Scandinavia so people can see them better. Japan uses blue cones for special or emergency vehicles. In India, green cones show areas that need care for nature or help people walk safely.

| Region/Country | Cone Color(s) | Intended Use / Regulatory Meaning |

|---|---|---|

| United States | Orange | Construction zones, road work; MUTCD/OSHA standards |

| United States | Lime Green | Service industries, high attention areas |

| Germany, UK | Red and White | General caution, temporary closures |

| Scandinavia | Yellow | Visibility in snowy conditions |

| Japan | Blue | Official/emergency vehicle areas |

| India | Orange | Construction zones |

| India | Green | Environmentally sensitive areas, pedestrian guidance |

Note: For the best visibility at night or on highways, experts say to use orange cones that are at least 28 inches tall with two shiny white bands.

Size and Color Chart

This chart helps buyers pick the right size and color for their needs:

| Height (in/cm) | Typical Use | Standard Color | Night Use (Reflective) |

|---|---|---|---|

| 12″/30 cm | Indoor, low-speed areas | Orange/Red | Not required |

| 18″/45 cm | Parking lots, events | Orange/Lime | Optional |

| 28″/71 cm | Road work, highways | Orange | 2 white bands |

| 36″/91 cm | High-speed roads, night | Orange | 2 wide white bands |

| 39″/100 cm | Major highways, airports | Orange/Red | Alternating stripes |

Picking the right size and color makes sure traffic cones follow safety rules and are easy to see in every situation.

Materials Overview

Traffic cones are made from different materials to keep people safe and make them last longer. The three main materials are PVC, rubber, and PE. Each one has special features that help with road work and safety.

| Material | Market Share | Key Properties | Regional Popularity |

|---|---|---|---|

| Polyethylene (PE) | Over 35% | Lightweight, UV resistant, recyclable, cost-efficient | North America, Europe |

| Rubber | Approx. 25% | High impact resistance, skid-proof | Asia-Pacific |

| Polyvinyl Chloride (PVC) | Nearly 40% | Flexible, high visibility, excellent color retention | Latin America, Middle East & Africa (MEA) |

PVC

PVC is a common material for traffic cones. It bends easily and is easy to see. PVC cones can handle bumps and bad weather. This makes them good for busy roads. Injection molded PVC cones are the strongest type. They meet tough safety rules. These cones last a long time outside and save money on big jobs. But PVC can break if it gets too cold or too much sun.

Tip: Pick injection molded PVC cones for outdoor jobs and busy roads.

Rubber

Rubber cones are strong and do not fall over easily. They stay up even when it is windy or rough. Rubber keeps its shape in hot or cold weather. These cones are great where there are lots of cars or tough weather. Rubber cones are heavy, so they are harder to move. But they almost never tip over.

- Rubber cones are best for long use in bad weather.

- They do not slip on wet or bumpy ground.

PE

PE cones are light and simple to carry. They block UV rays and cost less than other cones. PE cones are good for short jobs, events, or inside use. They can break in very cold weather and do not last as long outside as rubber or PVC cones.

Note: For short or indoor jobs, PE cones are a cheap choice.

Summary Table: Durability and Use Cases

| Material | Durability & Weather Resistance | Weight | Best Use Case |

|---|---|---|---|

| PVC | Good, but can crack in cold | Medium | Long-term outdoor, highways |

| Rubber | Excellent, all weather | Heavy | Extreme weather, high traffic |

| PE | Moderate, UV resistant | Light | Temporary, indoor, events |

Road Works

Road construction jobs need traffic cones to keep everyone safe. Bright orange cones with shiny collars are easy to see on busy roads. Workers use medium or large cones, from 18 to 36 inches tall. These cones show where work zones are and help cars go around dangers. They stop accidents and help traffic move better. The construction field uses the most cones because there are always new projects.

Event Crowd Control

People who plan events use traffic cones to control crowds and make safe walkways. Medium cones, 18 to 28 inches tall, are good for showing where to enter or leave. Bright or special colored cones help people know where to walk and keep areas organized. These cones help people find their way and stay out of closed spots. Event planning uses a lot of cones at concerts, festivals, and sports games.

Parking Lots

Parking lots use small traffic cones, usually 12 to 18 inches tall. These cones help cars find open spaces and show which spots are saved. They also help cars move in the right direction. Yellow or white cones are used most in parking lots. They are light, so people can move and store them easily. Stores, schools, and malls use these cones to make parking safer and faster.

Emergency Scenes

Emergency workers use big, bright traffic cones to mark accident spots and make safe areas. Cones that are 28 to 36 inches tall in orange or red warn drivers and protect workers. Putting these cones down fast helps control cars and keeps everyone safe in emergencies. Firefighters, police, and doctors use these cones at crashes, fires, and other urgent times.

Sports Training

Coaches and players use small, colorful traffic cones for practice and drills. These cones, 12 to 18 inches tall, mark lines and set up training spots. They are light, so you can move them quickly. Sports teams, schools, and gyms use these cones to help people get better at sports and keep things organized.

| Scenario | Cone Size | Cone Color | Placement & Purpose |

|---|---|---|---|

| Road Works | 18-36 inches | Bright Orange with Reflective Collars | Mark construction zones, guide traffic, highlight hazards. |

| Event Crowd Control | 18-28 inches | Bright or Event-Specific | Direct foot traffic, organize spaces, manage entry/exit points. |

| Parking Lots | 12-18 inches | Yellow or White | Guide vehicles, mark reserved spots, direct flow. |

| Emergency Scenes | 28-36 inches | Bright Orange or Red | Mark accident sites, warn drivers, create safe zones for responders. |

| Sports Training | 12-18 inches | Various Bright Colors | Mark boundaries, set up drills, easy to move for different exercises. |

Tip: Pick the right size and color of traffic cone for each job. This helps keep everyone safe and makes cones easy to see.

Buying Guide 2025

Reflective Collars

Reflective collars help people see traffic cones in any light. Buyers should pick collars made with strong retroreflective materials, like micro-prismatic technology. These materials bounce back light from car headlights. This makes cones easy to spot at night or in foggy weather. Fluorescent fabrics make cones even brighter during the day, especially when it is rainy or foggy.

Key things to look for in good reflective collars are:

- Micro-prismatic or high-quality retroreflective materials for extra brightness.

- Fluorescent fabrics that help cones stand out in daylight.

- Reflective strips placed so cones can be seen from all sides.

- Features like UV resistance and waterproofing to last outdoors.

- Meeting safety rules like OSHA, ANSI/ISEA 107, CSA Z96, AS/NZS 1906.1 Class 1, and EN 13356.

- Easy ways to attach collars, such as Velcro, stitching, or custom fits for different cones.

- Regular checks and cleaning to keep collars working well and following the rules.

Tip: Always look for labels that show the collar meets safety rules. This helps keep workers and drivers safe and follows the law.

Base Weight

A traffic cone stays up better if its base is heavy and the weight is spread out right. In windy or busy places, cones with heavier bases do not fall over easily. They stay standing even when cars pass close or the wind is strong.

The table below shows how different cones compare for stability:

| Cone Type | Total Weight (lb) | Tipping Angle (°) | Base Weight Distribution (%) | Stem Weight Distribution (%) |

|---|---|---|---|---|

| 7 lb. PVC Cone | 7 | 45 | 60 | 40 |

| 10 lb. PVC Cone | 10 | 55 | 60 | 40 |

| 7 lb. Enviro-Cone | 7 | 76 | 80 | 20 |

Heavier cones with more weight in the base can tip up to 76°. Lighter cones tip over at 45° to 55°. A wide, heavy base helps cones stay up in wind and when bumped.

Note: For windy or busy roads, pick cones with a low center of gravity. The base should be 70-80% of the total weight.

Stackability

It is important to store and move traffic cones easily, especially when buying many at once. Stackable cones save space, lower shipping costs, and are faster to set up. Buyers should check how well cones stack and store by following these tips:

- Stack cones straight up in one spot to keep their shape and make them easy to grab.

- Do not put heavy things on top of stacked cones so they do not bend or crack.

- Use racks, boxes, or cradles when moving cones to protect them and save space.

- Keep cones away from sharp tools or heavy machines that could break them.

- Use carriers or mounts to move cones safely and set them up quickly at work sites.

Tip: Stacking and storing cones the right way keeps them safe and makes setting up and cleaning up faster.

Choosing Traffic Cones

Picking the best traffic cones is about more than just color or size. Buyers need to think about how easy cones are to see, how steady they are, how to store them, if they follow safety rules, and how to get them delivered. Use this checklist and table to help you choose.

Buyer Checklist

Check these things before you buy to make sure you get the right cones:

- Make sure cones follow local and international safety rules (like MUTCD, EN 13422, AS 1742.3).

- Ask for certificates or test reports from the seller.

- Pick cones with good reflective collars and UV protection.

- Choose the right base weight (heavier for highways, lighter for inside or events).

- Check if cones stack well and if there are good storage options for big orders.

- Look for anti-skid bases for safety on wet or bumpy ground.

- Plan for delivery: check how long it takes, shipping prices, and customs rules.

- Compare sellers’ reviews, certificates, and help after you buy.

- Try to get discounts, free extras, or free shipping for big orders.

- Download the Traffic Cone Buyer’s Checklist (PDF) to help you remember these steps.

Comparison Table: Traffic Cones vs. Traffic Barrels

| Feature | Traffic Cones | Traffic Barrels |

|---|---|---|

| Typical Height | 18″–39″ (45–100 cm) | 36″–42″ (91–107 cm) |

| Base Weight | 3–15 lbs (1.4–6.8 kg) | 20–40 lbs (9–18 kg) |

| Reflective Collars | Yes, standard | Yes, larger surface area |

| Stackability | High | Moderate (nesting possible) |

| Storage Efficiency | Excellent | Good |

| Use Case | Lane marking, crowd control, events | Highway work zones, heavy traffic |

| Visibility | Good | Excellent (larger, more reflective) |

| Portability | Easy to carry and deploy | Heavier, less portable |

| Cost | Lower | Higher |

| Durability | Good (PVC, rubber, PE) | Excellent (HDPE, rubber) |

Note: For most road jobs and events, traffic cones are easy to use, move, and cost less. For big highway jobs or very busy roads, traffic barrels give more safety and are easier to see.

Compliance, UV Resistance, and Anti-Skid Bases

Buyers must check that cones meet all safety rules. In the U.S., look for MUTCD approval. In Europe, check for EN 13422. Australia uses AS 1742.3. Always ask for certificates or test results from the seller. ASTM and ISO certificates give extra proof.

UV resistance is important for cones used outside. Good PVC cones with UV protection last 3 to 5 years outdoors. Without UV protection, cones can fade, crack, or break in just two years. Keep cones in the shade or cover them when not in use to help them last longer.

Anti-skid bases stop cones from sliding on wet or rough ground. Pick cones with textured or rubber bases for the best grip.

Logistics for Overseas Buyers

Buying traffic cones from other countries can be tricky. Buyers need to follow rules, handle shipping, and make sure cones fit local needs. Online platforms help by making customs paperwork, tracking, and payments easier.

Common problems include:

- Late deliveries that slow down projects.

- Running out of cones because of bad planning.

- Extra costs like taxes and import fees.

- High shipping and freight prices.

Ways to solve these problems:

- Pick sellers with good shipping and clear prices.

- Have backup sellers to avoid running out.

- Try to get better prices and deals.

- Plan for taxes and import fees before you order.

- Pick shipping that is fast but not too expensive.

- Use websites that help with customs, money changes, and different languages.

- Build good relationships with sellers and check their reviews.

The table below shows how long and how much it costs to ship cones from different countries:

| Origin Country | Average Lead Time to U.S. Destinations | Shipping Cost Examples | Key Logistics Factors |

|---|---|---|---|

| China | 15-20 days to Los Angeles; up to 30 days to New York City | Higher due to ocean freight; offset by advanced logistics networks | Longer transit increases inventory costs; efficient ports and freight handling reduce some costs |

| Mexico | 2-5 days depending on destination (e.g., 2-3 days to Dallas, 4-5 days to New York City) | Lower costs due to proximity; e.g., $350 for 20-mile trip to San Diego, $2,600-$2,800 for Dallas-Fort Worth | Proximity reduces transit time and costs; affordable labor and fuel lower transportation expenses |

Tip: Order early and ship cones together to save money and avoid delays.

Supplier Evaluation and Bulk Purchasing Tips

Checking if a seller is reliable is very important when buying from other countries. Buyers should:

- Read reviews, check experience, and ask for customer feedback.

- Make sure the seller has the right certificates and follows safety rules (UL/ETL, CE).

- Check how long the cones will last and how strong they are.

- Make sure the seller offers help after you buy and has spare parts.

- See if you can get custom cones for special needs.

- Think about the total cost, including repairs and how often you need new cones.

- Plan for future needs and if cones work with new tech.

For big orders, try these tips:

- Learn prices and details so you know what is fair.

- Talk to many sellers to get better deals.

- Wait to add some pricier items for a better offer.

- Show lower prices from others to get a price match.

- Ask for trade discounts or use a third party for savings.

- Try to get free shipping or extras with your order.

- Be friendly with salespeople for better deals.

- Be ready to buy right away if the deal is good.

Checklist: Download the Traffic Cone Buyer’s Checklist (PDF) to keep these tips for your next order.

Frequently Asked Questions

Explore more:

- Learn about traffic cones for event management and how to select the right type for your venue.

- Discover the differences between traffic cones and barrels for road safety.

- Read our guide on traffic cones for sports training to optimize your facility.

People who buy traffic cones all over the world should remember these important tips to stay safe and save money:

- Pick the best material and size for your weather and project.

- Make sure cones are easy to see and follow safety rules.

- Buy from sellers who give good papers and help you if needed.

- Use a checklist and buying guide so you do not make mistakes and can spend less.

To learn more, get the free Traffic Cone Spec Sheet (PDF) or talk to trusted sellers. This will help you buy cones that are safe, follow the rules, and work well.

FAQ

What is the lifespan of a typical traffic cone?

A good traffic cone can last 3 to 5 years outside. If it has UV protection and is stored right, it lasts longer. Bad weather or lots of use can make it wear out faster.

How do traffic cones compare to traffic barrels for road safety?

| Feature | Traffic Cones | Traffic Barrels |

|---|---|---|

| Height | 18–39 inches | 36–42 inches |

| Weight | 3–15 lbs | 20–40 lbs |

| Visibility | Good | Excellent |

| Portability | Easy | Less portable |

Traffic barrels are easier to see and protect better if hit. Traffic cones are lighter and simple to move or set up.

Can I use traffic cones for indoor events?

Yes, you can use traffic cones inside. Event planners use them to guide crowds or block off areas. Pick small, light cones for inside jobs.

What certifications should buyers check before purchasing traffic cones?

Buyers should look for MUTCD, EN 13422, or AS 1742.3 certificates. These show the cones are safe and easy to see.

Where can I find a buyer checklist for traffic cones?

You can get the Traffic Cone Buyer’s Checklist (PDF). This list helps you pick the right cones and not make mistakes.

Tip: For more help, check out our traffic cones buying guide or see traffic cones for road construction.