Product Description

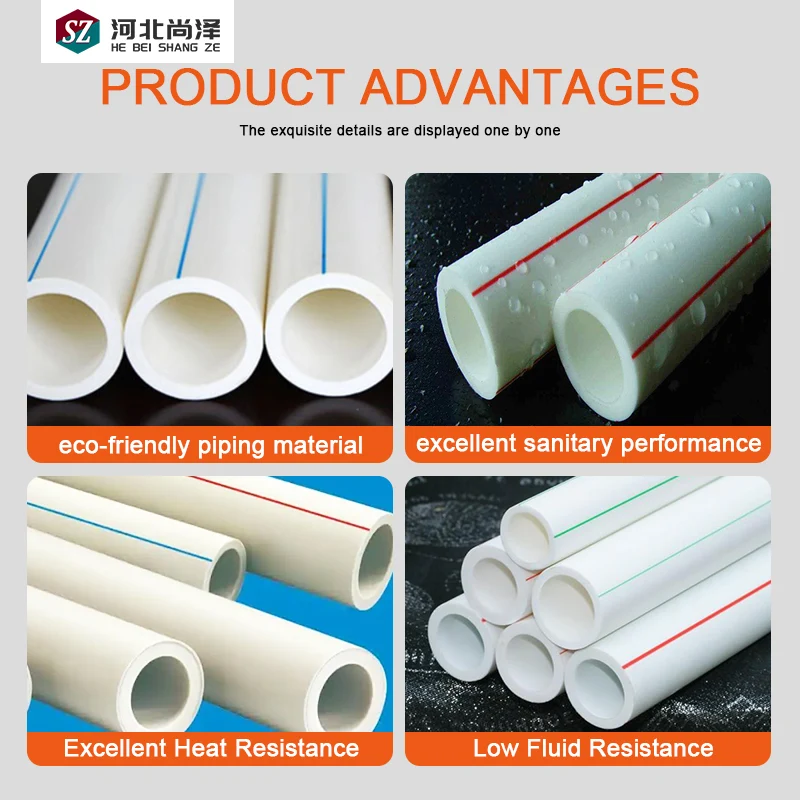

PPR pipe is a new type of eco-friendly piping material for both hot and cold water. It’s resistant to corrosion and buildup, and its smooth interior reduces water flow resistance. Made from polypropylene, it can handle temperatures from -30°C to 90°C. PPR pipes are joined using a hot-melt welding process, creating a strong and seamless connection. Available in white and green, these pipes come in various sizes from 16 to 160. They are ideal for both household water supply systems and large-scale construction projects.

PPR drinking water pipe is commonly used in developed countries, it uses homogeneous welding technology in hot and cold water transportation projects, and its comprehensive technical performance and economic indicators are far superior to other similar products. Particularly, its excellent sanitary performance, from the production to the waste recycling process can reach extremely high sanitary and environmental protection requirements.

Product Parameters

Project | Indicators | Test methods | Note: 1.Using a metal threaded inserts with a corrosion-resistant to connect plastic pipe fittings with metal pipes and water heater. | |||

| pipe | fittings | |||||

| Density g/cm3 (20ºC) | 0.89-0.91 | BG/T 1033 | ||||

| Thermal Conductivity(w/m.k. ) | 0.23-0.24 | BG/T 3399 | ||||

| Coefficient of linear expension (mm/mk) | 0.14-0.16 | BG/T 1036 | ||||

| Modulus of elastivity Nmm2 20ºC | 800 | BG/T1040 | ||||

| Tensile strength Mpa | ≥20 | BG/T 1040 | ||||

| Longitudinal reversion (135ºC±2ºC ) | ≥2% | BG/T 6671 | ||||

| Charpy impact test 15j 0±2ºC | Breakage rate <10% | BG/T 18743 | ||||

Hydraulic Test Tube | 20ºC 1h 16mpa | No leakage no rupture | No leakage no rupture | |||

| 9ºC 22h 4.2mpa | ||||||

| 95ºC 165h 3.8Mpa | ||||||

| Socket connection seal test | Experiental stress of 2.4 times the nominal | Breakage rete<10% | ||||

| Outside diameter mm | The average allowable deviation mm | Wall thickness (e) | |||

| Pipe series | |||||

| S5(1.25mpa) | S4(1.6mpa) | S3.2(2.0mpa) | S2.5(2.5mpa) | ||

| 16 | +0.3 | – | 2.0 | 2.2 | |

| 20 | +0.3 | 2.0 | 2.3 | 2.8 | 3.4 |

| 25 | +0.3 | 2.3 | 2.8 | 3.5 | 4.2 |

| 32 | +0.3 | 2.9 | 3.6 | 4.4 | 5.4 |

| 40 | +0.4 | 3.7 | 4.5 | 5.5 | 6.7 |

| 50 | +0.5 | 4.6 | 5.6 | 6.9 | 8.3 |

| 63 | +0.6 | 5.8 | 7.1 | 8.6 | 10.5 |

| 75 | +0.7 | 6.8 | 8.4 | 10.3 | 12.5 |

| 90 | +0.9 | 8.2 | 10.1 | 12.3 | 15.0 |

| 110 | +1.0 | 10.0 | 12.3 | 15.1 | 18.3 |

| 160 | +1.5 | 14.6 | 17.9 | 21.9 | 26.6 |

Detailed Photos

Product advantage

It can handle temperatures from -30°C to 90°C

welding: hot-melt welding process