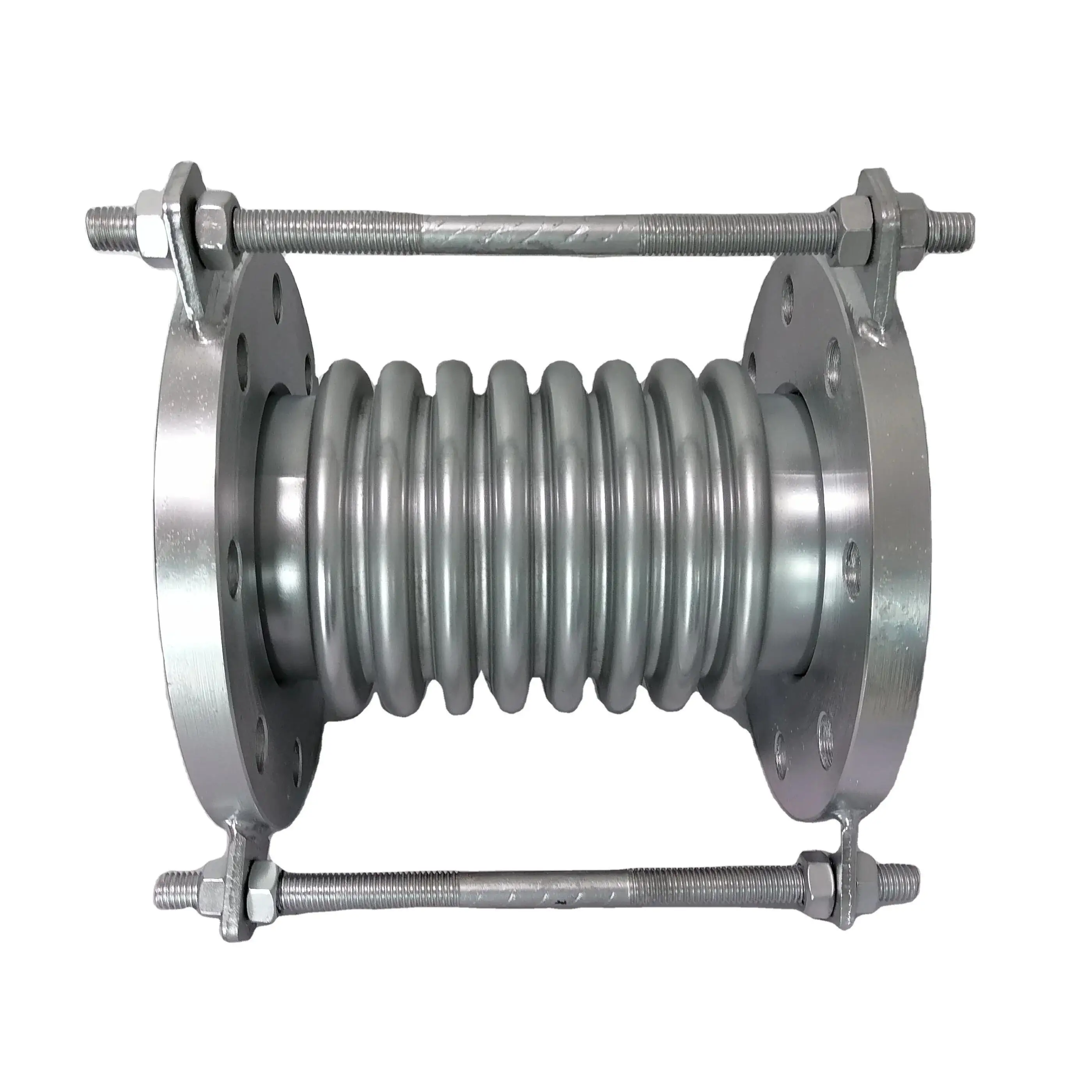

Strong compensation ability: can absorb displacement in multiple directions, including axial, lateral and angular. Vibration reduction and noise reduction: can effectively reduce the vibration and noise of the pipeline system. High temperature and corrosion resistance: suitable for a variety of harsh working environments. Easy installation: simple structure, low installation and maintenance costs.

Stainless Steel Bellows Flexible Metal Expansion Bellows Expansion Joint Bellow Compensator

|

Diameter

|

Quantity of ripple

|

Pressure Level

|

Effective area of corrugated tube

|

Maximum external diameter

|

||||||||

|

0.25

|

0.6

|

1.0

|

1.6

|

2.5

|

||||||||

|

Axial

compensation

|

Stiffness

|

Axial

compensation

|

Length

|

Toughness

|

||||||||

|

mm

|

mm

|

mm

|

N/mm

|

mm

|

mm

|

N/mm

|

CM2

|

mm

|

||||

|

32

|

8

|

25/21

|

22/26

|

20/26

|

18/63

|

|

16

|

225

|

||||

|

32

|

16

|

50/11

|

46/14

|

41/14

|

36/32

|

|

16

|

225

|

||||

|

40

|

8

|

25/28

|

22/44

|

20/44

|

18/89

|

15/98

|

23

|

244

|

||||

|

40

|

16

|

50/14

|

45/22

|

41/22

|

36/45

|

31/47

|

23

|

244

|

||||

|

50

|

8

|

25/30

|

22/51

|

20/70

|

18/70

|

15/106

|

37

|

259

|

||||

|

50

|

16

|

50/16

|

46/26

|

41/35

|

36/35

|

31/55

|

37

|

259

|

||||

|

65

|

8

|

33/28

|

30/35

|

26/44

|

22/55

|

15/138

|

55

|

270

|

||||

|

65

|

12

|

42/16

|

38/22

|

38/32

|

34/40

|

31/70

|

55

|

270

|

||||

|

80

|

8

|

40/20

|

36/26

|

34/33

|

28/41

|

19/68

|

81

|

284

|

||||

|

80

|

10

|

53/14

|

49/17

|

49/21

|

43/26

|

29/50

|

81

|

284

|

||||

|

100

|

6

|

45/47

|

45/60

|

40/75

|

35/93

|

25/54

|

121

|

304

|

||||

|

100

|

10

|

76/26

|

74/32

|

64/40

|

57/50

|

38/33

|

121

|

304

|

||||

|

125

|

5

|

48/38

|

42/47

|

38/59

|

34/74

|

29/117

|

180

|

334

|

||||

|

125

|

9

|

85/23

|

77/29

|

66/36

|

58/45

|

49/63

|

180

|

334

|

||||

|

150

|

5

|

49/42

|

44/50

|

40/62

|

34/78

|

29/92

|

257

|

364

|

||||

|

150

|

8

|

79/34

|

71/43

|

64/51

|

54/59

|

50/56

|

257

|

364

|

||||

|

200

|

4

|

52/49

|

46/55

|

42/68

|

38/78

|

29/97

|

479

|

442

|

||||

|

200

|

6

|

73/31

|

65/44

|

59/52

|

53/58

|

46/65

|

479

|

442

|

||||

|

250

|

4

|

72/30

|

65/34

|

59/42

|

52/45

|

34/111

|

769

|

507

|

||||

|

250

|

6

|

108/16

|

97/21

|

87/35

|

79/39

|

48/78

|

769

|

507

|

||||

|

300

|

4

|

72/51

|

65/55

|

59/59

|

52/65

|

47/55

|

1105

|

562

|

||||

|

300

|

6

|

108/32

|

97/35

|

73/37

|

79/31

|

71/47

|

1105

|

562

|

||||

|

350

|

4

|

72/58

|

65/62

|

59/67

|

52/74

|

47/71

|

1307

|

622

|

||||

|

350

|

6

|

108/38

|

87/41

|

87/44

|

79/48

|

71/45

|

1307

|

622

|

||||

|

400

|

4

|

72/58

|

65/68

|

59/62

|

52/68

|

47/81

|

1611

|

700

|

||||

|

400

|

6

|

108/36

|

97/39

|

87/43

|

79/47

|

71/47

|

1611

|

700

|

||||

|

450

|

4

|

108/32

|

97/35

|

87/37

|

79/41

|

47/75

|

1972

|

760

|

||||

|

450

|

6

|

162/20

|

145/22

|

131/23

|

118/25

|

71/52

|

1972

|

760

|

||||

|

500

|

4

|

108/59

|

97/64

|

87/68

|

79/75

|

71/45

|

2445

|

835

|

||||

|

500

|

6

|

162/34

|

145/37

|

131/39

|

118/43

|

106/28

|

2445

|

835

|

||||

|

600

|

4

|

108/74

|

97/80

|

87/85

|

79/94

|

71/82

|

3534

|

980

|

||||

|

600

|

6

|

164/42

|

145/45

|

131/49

|

118/53

|

106/48

|

3534

|

980

|

||||

|

700

|

4

|

108/67

|

97/72

|

87/77

|

79/85

|

71/103

|

4717

|

1110

|

||||

|

700

|

6

|

162/42

|

145/45

|

131/49

|

118/53

|

106/60

|

4717

|

1110

|

||||

|

800

|

4

|

120/88

|

108/95

|

102/102

|

94/112

|

71/95

|

5822

|

1265

|

||||

|

800

|

6

|

183/67

|

164/72

|

156/77

|

144/85

|

106/60

|

5822

|

1265

|

||||

|

900

|

4

|

120/84

|

108/90

|

102/97

|

94/107

|

82/123

|

7620

|

1186

|

||||

|

1000

|

4

|

120/91

|

108/98

|

102/105

|

94/116

|

82/117

|

9043

|

1286

|

||||

|

1000

|

6

|

183/59

|

164/65

|

156/71

|

144/85

|

125/84

|

9043

|

1286

|

||||

Bellows as an engineering material:

High elasticity and flexibility: Bellows can withstand large bends and twists without breaking or damaging, which makes it ideal for use in applications that require frequent movement or bending. Pressure resistance: Bellows can withstand high internal pressures and are suitable for the delivery of high-pressure fluids or gases. Corrosion resistance: Bellows made of certain materials have good corrosion resistance and can be used in chemical liquids or corrosive environments. Temperature resistance: Bellows can be designed to withstand extreme temperatures, from very low temperatures to high temperature environments. Shock and noise reduction: Bellows can absorb vibrations and reduce noise, and are suitable for occasions where shock and noise reduction are required. Easy to install and maintain: Bellows are usually designed to be easy to install and maintain, reducing installation time and costs.

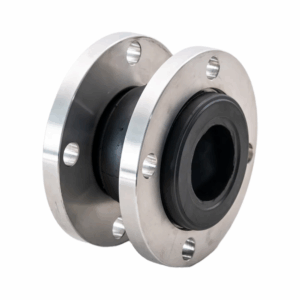

Reinforced Steam Corrugated Flange Stainless Steel Metal Bellows Compensator Rubber Expansion Joints

it is used for steam, gas, air, heavy oil, petroleum, chemical drugs, etc.

hundreds of construction projects and industrial enterprises at home and abroad, and has been widely praised. We will continue to uphold the business philosophy of “quality-oriented, honest and trustworthy, and comprehensive service” to provide new and old customers with high-quality rubber products, pipe fittings and other series of products.

2. Can be customized according to customer needs

3. check again before we send the goods

4. send the goods on time

5. The more you need, the cheaper the unit price is

A: We are factory.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T deposit+Balance 70% T/T before shippment.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q. Can you produce the products according to my own drawings?

A: Yes, we can produce the products according to your drawings that will be most satisfy you.

Reviews

There are no reviews yet.