Our Advantages

Product Description

BSPT Standard DN50 Flexible Union Type Threaded Rubber Expansion Joint for Water Threaded Rubber Compensator Screws Connector

|

Company Name

|

Zhengzhou Yongxing Pipeline Equipment Co., Ltd.

|

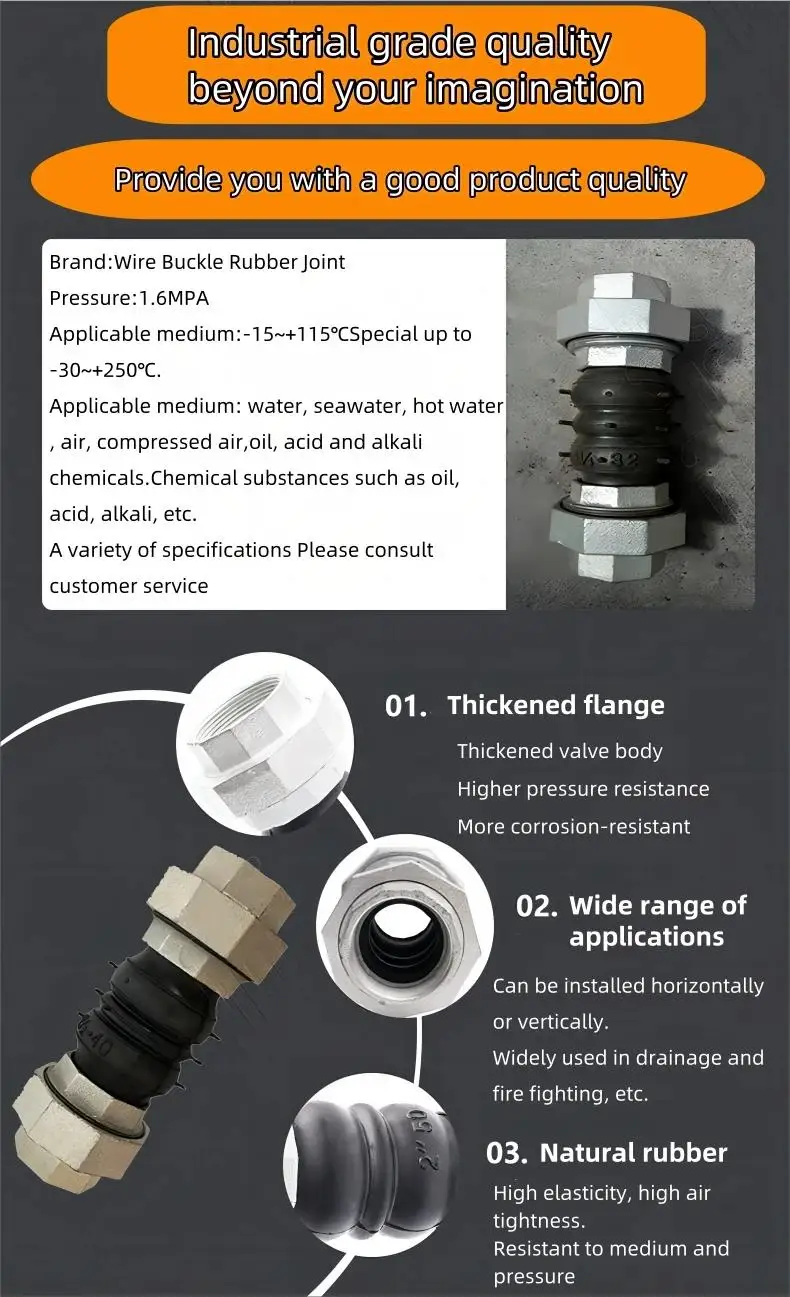

Rubber material

|

EPDM/NBR/NR/FKM/IIR/CR……

|

||

|

Product Name

|

Threaded Rubber Expansion Joint

|

Threaded surface

|

Smooth/Galvanizing

|

||

|

Product Model

|

KXT/JGD

|

Thread material

|

Malleable cast iron/SS304/SS316……

|

||

|

Flange pressure

|

PN6/10/16/25Mpa

|

||||

|

Flange Standard

|

BSPT/NPT

|

||||

|

Applicable media

|

Seawater, fresh water, hot and cold water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, refined oil, air, gas, steam and granular powder……

|

||||

|

Warranty period

|

1 year

|

||||

|

Product Features

|

Good sealing performance, shock and noise reduction function, adaptability to pipeline displacement, resistance to various media, easy installation and long service life. . . . . . .

|

||||

Product Advantages

Our company’s ordinary natural rubber sphere has a thickness of 10mm, 5 layers inside the sphere, 3 layers of cord rubber, and the inner layer of rubber is made of EPDM rubber.

Product Photos

Product Customization

Square Thread +Middle belt ring

Rubber Expansion Joint

BSPT SS304 thread + EPDM ball Middle rib

Rubber Expansion Joint

Malleable cast iron material + food grade ball

Rubber Expansion Joint

NPT malleable cast iron thread + NBR ball

Rubber Expansion Joint

BSPT malleable cast iron material + NR sphere without ribs in the middle

Rubber Expansion Joint

Carbon steel Triangular thread + EPDM rubber ball

Rubber Expansion Joint

Installation and precautions of threaded rubber expansion joints

Threaded rubber expansion joints are a type of fitting commonly used for pipe connections, which have the functions of shock absorption,noise reduction, displacement compensation, etc. Correct installation and precautions can ensure its normal operation and service life. The following are detailed installation instructions and precautions:

Installation instructions :

1. Check the integrity of the fittings: Before installing the threaded rubber expansion joint, carefully check whether the joint body, thread, gasket and other parts are complete, and whether there is any damage, deformation or defect. Make sure that the thread is clear and burr-free, the gasket has good elasticity, and there is no aging or cracking. If any problematic parts are found, they should be replaced in time to avoid affecting the installation quality and use effect.

2. Clean the pipe connection parts: Clean the ends of the pipes connected to the threaded rubber expansion joints to remove impurities such as rust, oil, and dust on the surface. For pipes with severe rust, sandpaper, wire brushes and other tools can be used for rust removal; oil stains can be cleaned with detergent or gasoline, and then wiped dry with a clean cloth. The pipe connection parts after cleaning should be kept clean and dry to ensure good sealing performance.

3. Apply sealant (optional): To enhance the sealing effect, evenly apply an appropriate amount of sealant, such as sealant, raw tape, etc., to the threaded part. When applying raw tape, start from the root of the thread and wrap it in a clockwise direction. The number of winding layers is generally 3-5 layers, and it is necessary to ensure that the winding is tight and flat to avoid looseness, wrinkles or breaks. When applying sealant, be careful not to apply too much to prevent the sealant from entering the pipe and affecting the flow of the medium.

4. Connect the rubber expansion joint to the pipe: Connect one end of the threaded rubber expansion joint to the thread of the pipe and tighten it slowly in a clockwise rotation. During the tightening process, ensure that the rubber expansion joint is consistent with the center line of the pipe to avoid deflection or distortion, otherwise it will affect the service life of the rubber expansion joint and even cause leakage. Tools such as wrenches can be used to assist tightening, but be careful to use moderate force to avoid damaging the thread due to excessive force.

5. Install the other end connection: Follow the above steps to connect the other end of the threaded rubber expansion joint to another pipe. After the connection is completed, check again whether the installation position of the rubber expansion joint is correct and whether the thread is tightened to ensure that the entire connection is firm and reliable.

6. Adjustment and fixation: After the installation is completed, adjust the threaded rubber expansion joint according to actual needs to keep it in a natural extension state to avoid excessive stretching, compression or twisting. For pipeline systems with support requirements, support devices such as brackets and hangers should be reasonably set to reduce the force on the rubber expansion joint and ensure its normal operation.

Precautions:

1. Avoid overpressure use: The threaded rubber expansion joint has a specific working pressure range. During use, ensure that the medium pressure in the pipeline does not exceed the rated working pressure of the rubber expansion joint. Overpressure use may cause the rubber expansion joint to rupture, deform or seal failure, causing safety accidents. When designing and installing the pipeline system, the threaded rubber expansion joint of appropriate specifications should be selected according to the actual working conditions, and the pressure in the pipeline should be strictly controlled.

2. Prevent the temperature from being too high or too low: The material of the rubber expansion joint has a certain adaptability to temperature. Too high or too low temperature will affect its performance and service life. Generally speaking, the applicable temperature range of ordinary rubber expansion joints is between -20℃ and 80℃. If the medium temperature in the pipeline exceeds this range, a rubber expansion joint of a special material should be selected, such as a high-temperature resistant fluoro-rubber expansion joint or a low-temperature resistant silicone rubber expansion joint. At the same time, care should be taken to avoid long-term exposure of the rubber expansion joint to high or low temperature environments, such as near a heat source or in a cold outdoor environment.

3. Avoid chemical medium corrosion: If the medium transported in the pipeline is corrosive,corrosion-resistant rubber expansion joint materials should be selected, such as chloroprene rubber, nitrile rubber, etc. Before installation, it is necessary to understand the chemical properties of the medium and ensure that the material of the rubber expansion joint is compatible with the medium. At the same time, the appearance of the rubber expansion joint should be checked regularly. If any signs of corrosion are found, it should be replaced in time to avoid leakage.

4. Regular maintenance inspection: During the use of threaded rubber expansion joints, regular maintenance inspections should be carried out. The inspection content includes the tightness of the thread,whether the appearance of the rubber expansion joint is damaged, deformed, aged, etc., and whether there is leakage in the sealing part. If problems are found, appropriate measures should be taken in time to deal with them, such as tightening the thread, replacing damaged rubber expansion joints, etc. Regular maintenance inspections can timely discover potential safety hazards and ensure the normal operation of the pipeline system.

5. Prevent mechanical damage: During installation and use, avoid mechanical damage to the threaded rubber expansion joint, such as scratches and collisions from sharp objects. Mechanical damage may damage the structure of the rubber expansion joint,reduce its performance, and even cause leakage. When transporting and installing the rubber expansion joint, handle it with care to avoid collision with other hard objects; during the operation of the pipeline system, prevent surrounding objects from scratching or squeezing the rubber expansion joint.

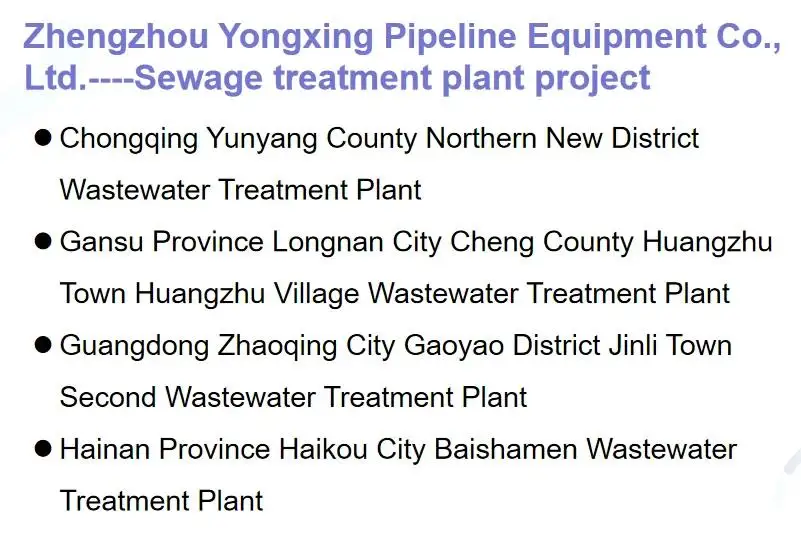

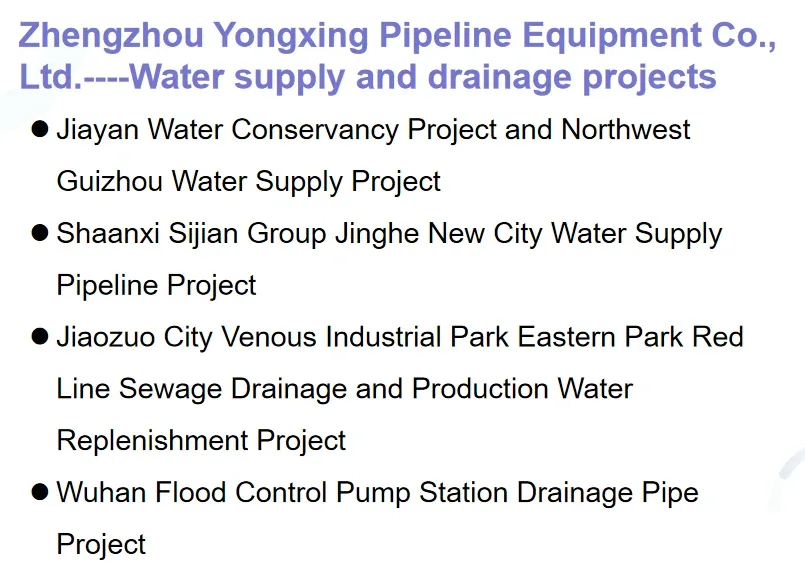

Project Case

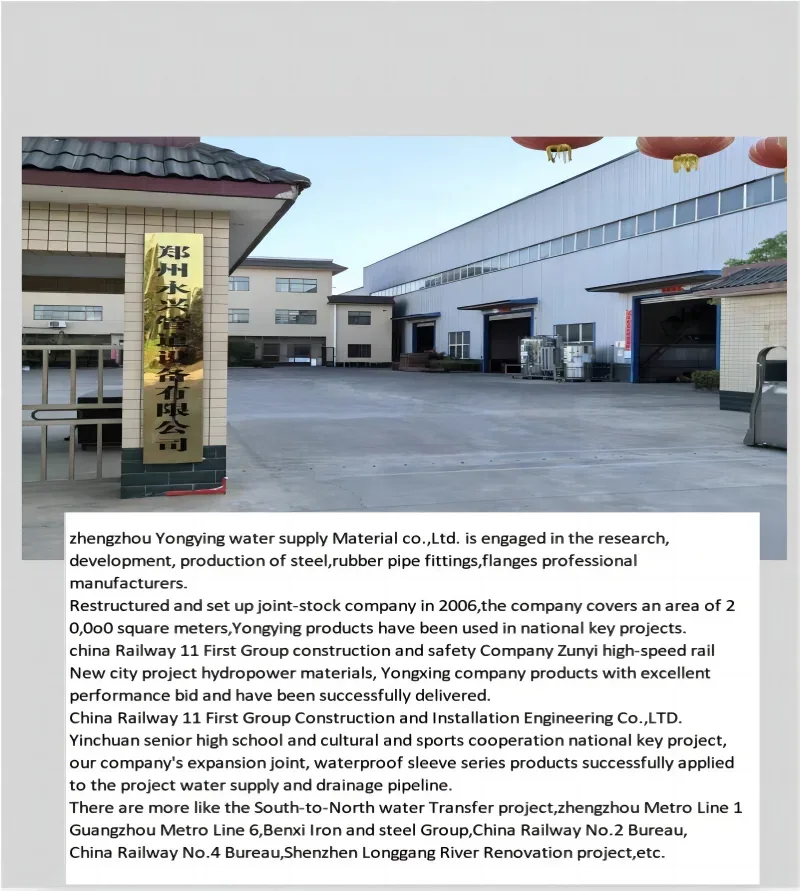

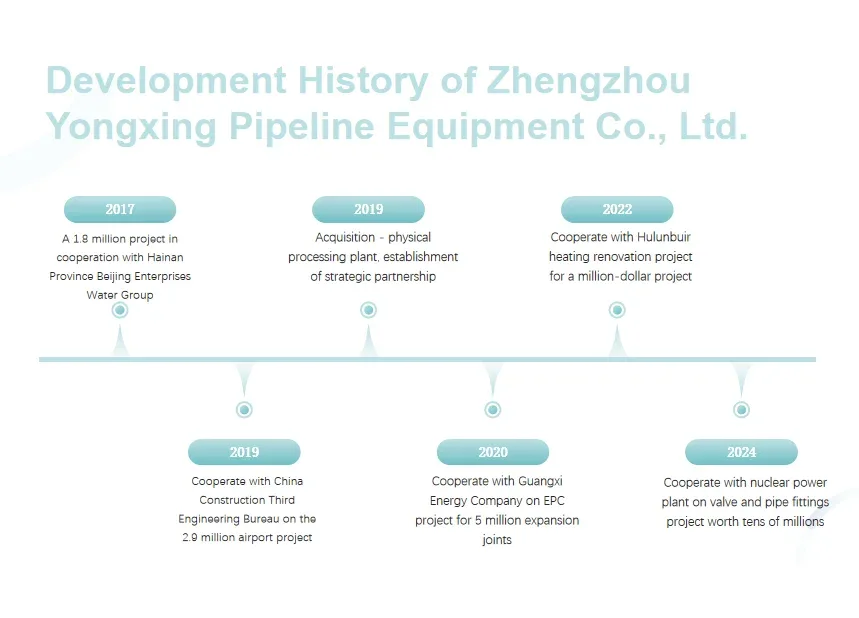

Company Profile

BSPT Standard DN50 Flexible Union Type Threaded Rubber Expansion Joint for Water Threaded Rubber Compensator Screws Connector

FAQ

Q : Are you trading company or manufacturer?

A: We are manufacturer of flange, expansion joint,rubber joint, bellow, dismantling joint, dresser coupling, lift check valve,flange adapter and flange with more than 12-year experience.

Q: Do you have products catalog?

A: Yes, we have. Please tell me your email or instant messager, we will send our catalog.

Q: Can you provide drawings and technical data?

A: Yes, our professional technical department will design and provide drawings and techical data.

Q: Do you provide samples? Is it free or charged?

A: Yes, we can offer sample free but shipping charges covered by customer.

Q: Have your products been exported?

A: Yes, they have been exported to USA, Canada, Australia, Russia, Chile, Panama, Nicaragua, UAE, Saudi Arabia, Egypt, Sri Lanka, Nigeria, Vietnam, Indonisia, Singapore, Greece, Netherland, Georgia, Romania, Ireland, India, Thailand,

Pakistan, Philippines…

Pakistan, Philippines…

Q: Can the products be manufactuered by customer’s requirement?

A: Yes, the specifications stated above are the standard ones, we can design and manufacture as requirement.

Contact us for more details about price and packing, shipping and discount!

Reviews

There are no reviews yet.