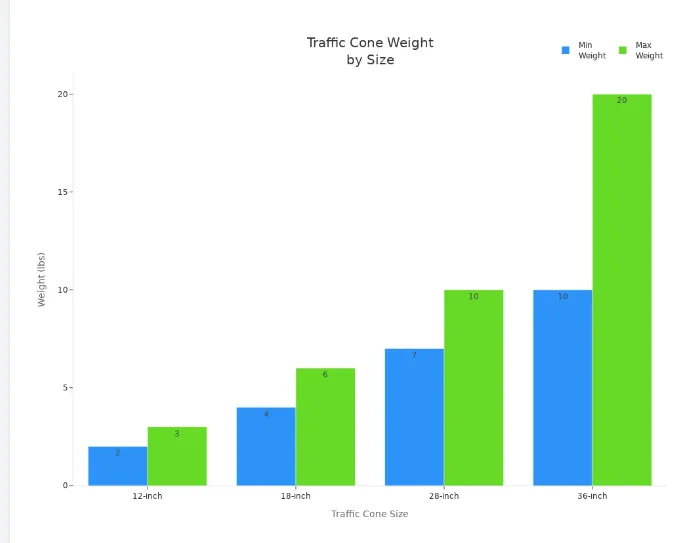

Choosing the right traffic cones can be hard. There are many choices for warehouses, city streets, or highways. In 2025, industry data says a 28-inch cone weighs 7 to 10 pounds. A 36-inch cone usually weighs about 10 pounds. Heavy-duty 36-inch cones can weigh up to 12 pounds. The table below shows weight ranges for 12-inch, 18-inch, 28-inch, and 36-inch cones. It shows how material and size change the weight.

Key Takeaways

- Traffic cones can weigh from 1 to 12 pounds. The weight depends on their size and what they are made of. PVC cones are lighter. They work well inside or for short times. Rubber cones are heavier. They are better for windy or busy outdoor places. Heavier cones with wide or weighted bases do not fall over in strong wind. They also stay up when cars go by fast. This helps keep people safe. For city roads, use 28-inch cones that weigh 7 to 10 pounds. For highways, use 36-inch cones that weigh 10 to 12 pounds. Always check local rules and MUTCD standards. This helps you pick cones that are safe and easy to see.

Hebei Shangze Rubber & Plastic Products Co., Ltd. has been deeply rooted in the traffic-cone industry for more than 20 years and has grown into a specialized manufacturing,we can provide design, production, sales, and after-sales service. The company owns a self-built, 18,000 m² modern plant equipped with more than 30 world-class injection-molding, blow-molding, rubber-vulcanizing, and CNC precision-machining centers, enabling flexible mass production of up to 50,000 cones per day.

Weight classes span eight graduated levels—0.85 kg, 1.2 kg, 1.5 kg, 2.1 kg, 2.5 kg, 3.2 kg, 4 kg, 4.5 kg, and up to 5.5 kg—meeting both light-duty needs such as temporary detours and residential complexes, as well as heavy-duty applications like highway construction and emergency response. Heights are available in a full range from 45 cm, 50 cm, 55 cm, 60 cm, 70 cm, 75 cm to 90 cm, achieving the optimal balance between visibility and compact storage.

Reflective sheeting system is available in two configurations: single-band economy grade and double-band enhanced grade. Sheeting levels include:

Engineering-grade reflective film: retro-reflectivity ≥ 250 cd , compliant with GB/T 18833-2012 Class IV, suitable for ordinary roads.

High-intensity prismatic film: micro-prismatic structure, retro-reflectivity ≥ 500 cd/(lx·m²), certified to ASTM D4956 Type III, providing a nighttime visibility distance up to 300 m, designed for highways, tunnels, and severe-weather conditions.

Traffic Cone Weight Overview

Quick Answer

In 2025, the weight of a standard traffic cone depends on its size and what it is made from. Most 28-inch and 36-inch traffic cones weigh between 7 and 12 pounds.

Weight Range Table

Traffic cones come in different sizes and materials. Each type is made for a certain place or job. The table below shows the most common sizes, their weights, and what they are made of in 2025:

| Height | Material | Weight (lb) | Common Use |

|---|---|---|---|

| 12″ | PVC | 1–1.5 | Indoor marking |

| 18″ | PVC | 4–6 | Parking lots |

| 28″ | PVC | 7 | City streets |

| 28″ | Rubber | ≈10 | High-traffic roads |

| 36″ | PVC | 10 | Highway work zones |

| 36″ | Rubber + base | 12 | Freeway construction |

Note: PVC cones are light and can handle bad weather. This makes them good for short jobs or inside buildings. Rubber cones are heavier and last longer. They stay in place better on busy roads or when it is windy. Weighted bases help cones stay up on highways and at construction sites.

The weight of a traffic cone changes with the material. PVC cones are about one third lighter than rubber cones of the same size. PE cones are strong but not too heavy. Heavy-duty cones have stronger bases to keep them steady. Cones with weighted bases are needed in windy places or where cars go fast. These cones do not fall over easily and help keep people safe.

The weight of a traffic cone matches how it is used. A 12-inch cone works best inside. A 36-inch cone with a rubber base is good for freeway work. Most cones are between 12 and 36 inches tall. Each size is made for a special job based on how big and heavy it is.

Factors Influencing Traffic Cone Weight

Knowing what makes a traffic cone heavy or light helps people pick the right one. There are four main things that change how much a traffic cone weighs. These are the material, size, base design, and any extra parts. Each of these things also changes how well the cone works.

Material

The material used to make a traffic cone is very important. It changes how heavy and strong the cone is. PVC traffic cones are lighter and easy to move. They are good for inside or short-term use. Rubber traffic cones are heavier and do not tip over as easily. They work better in windy places or on busy roads. Some cones use recycled plastic or a mix of LDPE and rubber. This makes the base heavier and helps stop the cone from falling over.

| Cone Type | Material Composition | Total Weight (lbs) | Weight Distribution (Base/Stem) | Stability & Durability Impact |

|---|---|---|---|---|

| PVC Cone | Polyvinyl Chloride (PVC) | 7 or 10 | 60% / 40% | The stem is heavier, but it is less stable. It can break in very hot or cold weather. |

| Enviro-Cone | LDPE + Recycled Rubber | 3 to 12 | 80% / 20% | The base is heavier, so it stands up better in wind. It lasts longer and is better for the environment. |

Size

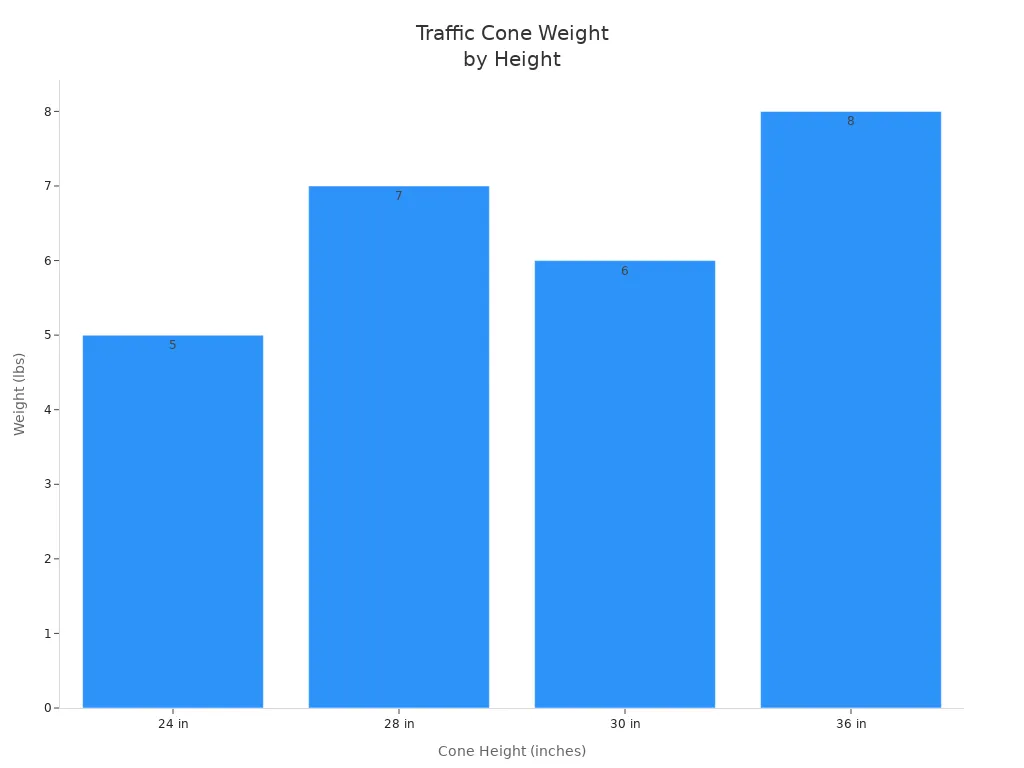

Traffic cones come in many sizes, from 12 inches to 36 inches tall. Bigger cones weigh more and are easier to see. They also stand up better and do not fall over as much. Every time you go up in size, a PVC cone gets about 2 or 3 pounds heavier. The chart below shows how weight goes up as cones get taller.Base Design

The way the base is made changes how heavy and steady the cone is. Solid rubber bases make cones heavier and help them grip the ground. This keeps them standing in strong wind or on busy roads. Some bases can be filled with water or sand. This makes them easy to move and store. Collapsible cones are not as heavy. They are good if you need to move them a lot.

- Solid rubber bases help cones stay up in wind.

- Water or sand-filled bases are easy to move and change weight.

- Wide, anti-slip bases keep cones from tipping over.

- Strong materials help cones last in bad weather.

Accessories

Extra parts can make a traffic cone heavier. Weighted bases add the most weight. For example, a 7-pound rubber weight can be used on a 28-inch cone. Reflective collars are very light but help people see the cone at night. LED beacons or signs can add up to half a pound.

| Accessory Name | Weight Added | Material | Purpose |

|---|---|---|---|

| 7 lb Rubber Weight | 7 lbs | Rubber | Helps cones stay up in wind and traffic |

| Reflective Collar | <0.2 lbs | Retroreflective | Makes cones easier to see at night |

| LED Beacon | 0.3–0.5 lbs | Plastic/Electronic | Makes cones easier to see in the dark |

Note: The color of a traffic cone does not make it heavier or lighter. Bright colors help people see the cone and stay safe.

Traffic Cone Selection Guide

Indoor & Warehouse Use

Picking the right traffic cones for inside or warehouse spaces is important for safety. Lightweight cones with rubber bases work well on smooth floors. These cones are easy to carry and set up. They are good for marking hazards or making temporary paths. Most places use smaller cones like 12-inch or 18-inch sizes. These cones are easy to see but not too big.

| Base Type | Features | Ideal Use Case |

|---|---|---|

| Rubber Base | Non-slip, stable | Indoor spaces, warehouses |

| Hollow Base | Lightweight, portable | Temporary, low-traffic |

Tip: Rubber bases help cones not slip on shiny floors. Reflective collars make cones easier to see in dark places.

There are no strict rules for indoor cones in 2025. Many places pick cone colors that fit their safety needs. Some use black or white cones instead of orange ones. Safety gets better when cones have rubber bases and reflective bands.

City Road Use

City roads need cones that are easy to see and hard to knock over. For roads where cars go faster than 25 mph, the MUTCD says to use cones at least 28 inches tall. Heavier cones, about 7 to 10 pounds, do not tip over easily. Rubber or weighted bases make cones even more steady. This is important in busy or windy cities.

- Use 28-inch or 36-inch cones for busy roads.

- Pick cones that weigh 9 to 12 pounds for best results.

- Choose PVC or rubber cones that can handle sunlight.

- Add reflective collars so cones can be seen at night.

| Cone Type | Height | Weight | Compliance |

|---|---|---|---|

| Standard | 28″ | 7–10 lb | MUTCD, NCHRP-350 |

| Heavy-duty | 36″ | 10–12 lb | MUTCD, NCHRP-350 |

Note: Rules can be different in each city or state. Always check local rules before buying cones.

Highway Construction

Highway work needs the biggest and heaviest cones to keep people safe. The MUTCD and NCHRP-350 say to use 36-inch cones that weigh 10 to 12 pounds. These cones are used on highways where cars go very fast. Cones must have reflective collars so drivers can see them at night or in bad weather.

- Use 36-inch cones for highways and interstates.

- Make sure each cone weighs at least 10 pounds.

- Pick cones with wide bases and reflective bands.

- Check that cones meet MUTCD and NCHRP-350 rules.

- Stackable or grabber cones are easy to move and use.

Safety Tip: Heavy cones with weighted bases stay up in strong wind and fast traffic. This helps stop accidents from happening.

Why Weight Matters for Traffic Cones

Safety & Wind Resistance

How much a traffic cone weighs is very important for safety. This is especially true in places with strong wind or lots of cars. Heavy cones do not fall over when wind blows or cars drive by. Light cones can tip or slide, which is dangerous for drivers and workers. The weight in the base and the way the cone is built help it stay put and not move.

| Feature | 28-Inch Traffic Cones | 36-Inch Traffic Cones |

|---|---|---|

| Stability | Moderate; less stable in wind | High; resists wind and displacement |

| Base Weight | Around 7 lbs | Heavier, typically 10-12 lbs |

| Suitability | Lower-speed, urban environments | High-speed, windy, and high-traffic areas |

A 36-inch cone with a 10 to 12 pound base is very steady. These cones are easy to see and work well on highways. Lighter 28-inch cones weigh about 7 pounds. They are good for city roads but might fall in strong wind. Wind tunnel tests show a 10-pound cone with a heavy base can stand up in winds as fast as 270 mph. This strong wind resistance is needed to keep highways safe.

Compliance Standards

In 2025, there are rules for how much traffic cones should weigh. The MUTCD and NCHRP-350 say how tall and heavy cones must be for each place. On highways, cones need to be at least 36 inches tall and weigh 10 to 12 pounds. For city roads, 28-inch cones must weigh at least 7 pounds. Inside buildings or warehouses, lighter cones from 1 to 3 pounds are allowed.

Note: Following these rules makes sure cones are safe and easy to see. People who buy cones should always check the newest rules before they order.

References

The Manual on Uniform Traffic Control Devices (MUTCD) is the main guide for traffic cone weight rules in the United States. The Federal Highway Administration makes and updates this guide often. The MUTCD tells you the smallest height, weight, and reflectivity for cones on public roads. It also lists crash safety rules like NCHRP-350 and MASH. These rules make sure cones are safe for city streets and highways. People who buy cones use the MUTCD to find the newest and official rules. You can find the manual online. It has easy-to-read charts and tables.

The MUTCD is still the top rulebook for traffic cone rules in 2025. It explains everything from cone height to base style. This helps make sure all cones on American roads follow federal safety rules.

Traffic safety equipment sellers, like Traffic Safety Store, sell products that follow MUTCD rules. These sellers show the exact weights for each cone size. For example, a 28-inch cone weighs 7 pounds and a 36-inch cone weighs 10 pounds. Their websites often mention the MUTCD and NCHRP-350. This shows their cones meet or beat federal rules. This info helps buyers pick cones that fit both the rules and their own needs.

Industry sites like Traffic Safety Warehouse give more details. They talk about all cone sizes and weights. This goes from light 12-inch cones for inside use to heavy 36-inch cones for highway jobs. These sites confirm that federal and local laws set certain weights and visibility rules. All these rules are based on the MUTCD.

Authoritative Sources:

- Manual on Uniform Traffic Control Devices (MUTCD) – Federal Highway Administration

- Traffic Safety Store – Traffic Cone Weights and Specifications

- RoadTrafficSigns.com – Cone Weight Guide

For the best and newest info on traffic cone weight, always check the MUTCD and trusted sellers.

Picking the right traffic cone weight keeps everyone safe and follows the rules. Buyers need to think about the cone’s size, what it is made of, and where it will go.

- Heavy-duty cones have thicker parts and bigger bases to stay steady.

- Reflective strips help people see cones when it is dark.

- Heavier cones do not blow away or move if a car hits them, so they work well on busy roads.

| Cone Height (Inches) | Weight (lbs) | Compliance Standards |

|---|---|---|

| 28 | 7 | MUTCD |

| 36 | 8 | IATSS |

Always look at the weight chart and check the latest rules before you buy. This helps make sure cones work well and keep people safe.

FAQ

How much does a traffic cone weigh on average?

Most standard 28-inch and 36-inch traffic cones weigh between 7 and 12 pounds. The exact weight depends on the material and base design. Refer to the traffic cone weight chart for specific sizes and materials.

What is the difference in weight between rubber and PVC cones?

Rubber cones weigh about 30–40% more than PVC cones of the same size. For example, a 28-inch PVC cone weighs 7 pounds, while a rubber version can reach 10 pounds.

Rubber cones offer better wind resistance and durability for outdoor use.

How does traffic cone weight affect wind resistance?

Heavier cones stay upright in strong winds. A 10–12 pound cone can resist winds up to 270 mph. Lighter cones may tip over in gusty conditions.

| Cone Weight | Wind Resistance |

|---|---|

| 7 lb | Moderate |

| 12 lb | Excellent |

Are heavier cones harder to ship or move?

Yes. Heavier cones cost more to ship and require more effort to move. For frequent relocation, lighter PVC cones work best. For permanent or outdoor use, heavier cones provide better stability.

Where can I find a traffic cone weight chart?

Procurement managers and engineers can download a printable traffic cone weight chart (PDF) here:

Download the printable weight & spec sheet (PDF)

Always check the latest chart before purchasing to ensure compliance and safety.