What is the Function of a Compensator in a Pipeline

You depend on the compensator in the pipeline to keep things safe and working well. The role that the compensator plays in the pipeline is crucial, especially when temperatures fluctuate, causing pipes to expand or contract. The compensator accommodates this movement, reducing stress on the pipeline. This function helps prevent leaks and minimizes the likelihood of failure. Additionally, using a compensator helps avert property damage and addresses safety issues that can arise when pipelines shift or break.

Key Takeaways

- A compensator helps keep pipelines safe. It absorbs movement from temperature changes. This stops leaks and damage.

- Expansion loops help control how pipes move. They reduce stress and make pipelines last longer.

- Bellows compensators lower vibrations. They handle pressure changes. This makes systems quieter and more reliable.

- Check your compensator often for damage. This helps you find problems early and keeps things safe.

- Pick the right compensator for your pipeline. This helps it work well and meet safety rules.

Temperature changes can make pipes get bigger or smaller. The compensator helps the pipeline handle this movement. It keeps everything steady and safe. Using a pipe compensator lets the pipeline deal with heat without hurting the joints. Expansion loops look like U or Z shapes. These loops help control how much the pipes move. They stop the pipeline from breaking when it gets hot or cold. This design helps control expansion and keeps things working well.

- Expansion loops take in movement from temperature changes.

- These loops lower stress and make the pipeline last longer.

- You keep the pipeline safe from damage caused by heat.

A bellows compensator helps lower stress and shaking in the pipeline. When you put in a bellows compensator, the system can adjust for mistakes during setup. It can also take in movement from heat or force. The bellows can bend in different ways. This means they fit many kinds of pipeline changes. You also cut down on shaking from pumps or machines. Rubber compensators are stretchy and soft. They soak up shaking and keep it from spreading. This protects other parts and makes things quieter.

- Bellows compensators fix setup mistakes and take in movement.

- They handle many types of pipeline bending, even from earthquakes.

- Rubber compensators stop shaking from spreading and keep things steady.

- You help your equipment last longer by controlling shaking and pressure.

Compensators also help stop leaks and breakdowns. A bellows compensator protects the pipeline from too much pressure. The bellows take in movement and keep the system from cracking. This means you spend less on fixing things. You also keep the system strong, which is safer. A pipe compensator helps you avoid sudden problems that could be dangerous or cause damage.

- Compensators let pipes grow and shrink safely.

- They soak up shaking and keep pipes from getting stressed.

- You save money on repairs and keep things safe.

- The bellows compensator helps the pipeline last longer by stopping leaks and cracks.

Tip: Always look at your bellows compensator for damage. Checking often helps you find problems early and stay safe.

Using the right pipe compensator lets the pipeline move without losing pressure or breaking. This is important for keeping your system safe, strong, and working for a long time.

A compensator helps control how much a pipeline moves. When it gets hot or cold, the pipeline can get longer or shorter. The bellows inside the compensator work like a spring. They stretch or squeeze to take in this movement. This stops the pipeline from bending too much or breaking. You can look at the table below to see how these ideas work:

| Principle | Explanation |

|---|---|

| Displacement Control | Keeps movement steady and lowers hard work on parts. |

| Energy Release Rate | Changes with how bendy the bellows and pipeline are. |

The bellows compensator uses displacement control to keep things steady. The bellows move with the pipe, so you do not get sudden cracks. In systems with high pressure, the bellows compensator takes in movement without making big pushing forces. This keeps the pipeline safe and working well.

- Bellows compensators help with changes from heat.

- They let the pipeline move without extra force.

- You keep the pipeline safe from damage when temperatures change.

A bellows compensator makes the pipeline system more flexible. The bellows can bend, stretch, or squeeze in many ways. This lets you put the pipeline in small spaces or around corners. The bellows also help when the pipeline shakes or vibrates. They take in the energy and stop it from moving to other parts.

- You use a bellows compensator to handle shaking from pumps or machines.

- The bellows keep the pipeline steady during earthquakes or heavy use.

- You lower noise and help the system last longer.

Picking a bellows compensator makes your pipeline safer and stronger. The bellows work every day to keep things running well, even if things change.

Types of Pipeline Compensators

When you pick a pipe compensator, you should know the main types. Each type works best for certain jobs in a pipeline. Here are the most common choices.

Bellows Compensator

A bellows compensator has thin metal sheets shaped like waves. These sheets are called bellows. The bellows stretch and squeeze when the pipeline moves. This type can handle heat, shaking, and movement. You use bellows compensators where the pipeline gets very hot or has high pressure. The bellows help stop leaks by taking in movement before it reaches the joints. You find bellows compensators in power plants, chemical factories, and heating systems.

Note: Check your bellows for cracks or damage. This helps your bellows compensator work well and keeps your pipeline safe.

Axial and Lateral Compensators

An axial pipe compensator handles movement along the pipeline’s length. The bellows in this type stretch in and out. They take in changes from heat. A lateral pipe compensator works when the pipeline moves side to side. The bellows in a lateral pipe compensator bend sideways. You use these types in long, straight pipelines or where pipes turn corners.

- Axial pipe compensator: Handles movement in a straight line.

- Lateral pipe compensator: Handles movement from side to side.

Universal and Angular Compensators

A universal pipe compensator has two bellows with a connector in the middle. This design lets the bellows move in many directions. You use a universal pipe compensator when the pipeline needs to handle both straight and sideways movement. An angular pipe compensator lets the bellows bend at an angle. You use this type when the pipeline turns or needs to move in a curve.

| Type | Main Feature | Best Use Case |

|---|---|---|

| Universal | Moves many ways | Complex pipeline paths |

| Angular | Bends at an angle | Pipe turns and curves |

You can choose the right pipe compensator by looking at how your pipeline moves. Each bellows compensator type helps keep your system safe and working well.

Benefits and Uses in Pipelines

Longer Service Life

You want your pipeline to last a long time. A pipe compensator helps make this happen. The bellows inside take in movement from heat and cold. This stops the pipeline from cracking or wearing out fast. Using a pipe compensator lowers the risk of damage from pressure changes. The Pipeline and Hazardous Materials Safety Administration checks pipelines before raising pressure. They look at design, building, and care. This careful check means your pipeline meets high standards. Because of this, your pipeline lasts longer and stays strong.

Better Safety and Reliability

Safety and system strength are important to you. A compensator lets the pipeline move safely when heat or pressure changes. The bellows take in stress and keep it away from weak spots. This lowers the chance of leaks or sudden breaks. Your system keeps running well. Using a pipe compensator helps stop accidents and keeps people and property safe. The bellows work every day to keep your system safe and steady.

Tip: Check your bellows often. This helps you find problems early and keeps your pipeline safe.

Industry Uses

Many industries use compensators. Power plants use bellows to handle heat and pressure. Chemical factories use pipe compensators to keep flow steady. Oil and gas companies use bellows for long pipelines. Water treatment plants use compensators to protect their machines. No matter the industry, a compensator helps your system last longer and stay strong.

| Industry | Main Use for Compensator |

|---|---|

| Power Generation | Handles heat and pressure |

| Chemical Processing | Maintains stable flow |

| Oil & Gas | Manages pipeline movement |

| Water Treatment | Protects equipment |

Picking the right compensator keeps your pipeline safe. First, think about how your pipeline moves. Some pipelines stretch straight. Others bend or twist. You also need to think about temperature and pressure. High heat or pressure can change how a pipe compensator works. The environment matters too:

- Lots of moisture can make the bellows rust and less flexible.

- Humid air can cause mold, which might block the bellows.

- Cold, wet weather can freeze water on the bellows. This makes them hard and easy to break.

Check the material and size of the pipe compensator. Make sure it fits your pipeline for safety and strength.

Doing regular checks helps your compensator last longer. It also keeps your pipeline safe. You should:

- Look at the bellows often for cracks or changes.

- Make a maintenance plan using the maker’s advice and your own experience.

- Keep extra bellows in a cool, dry place away from the sun.

- Follow the maker’s rules when you change the compensator.

- Make sure the supports are the right size and can hold the weight.

Good care helps your system work well and stops sudden problems.

Sometimes, your compensator might have problems. Here are some common issues and ways to fix them:

| Common Failure | Troubleshooting Method |

|---|---|

| Pressure spikes/surges | Check for things blocking the flow, change valve settings, or add a pressure relief valve. |

| Inconsistent performance | Look for damage or wear, change valve settings, or get a new compensator. |

| Leakage | Check for damage, change seals or gaskets, or get a new compensator. |

| Mechanical failure | Look for damage, change broken parts, or get a new compensator. |

Tip: If you see leaks or changes, check your bellows and pipe compensator. Fixing things early keeps your pipeline safe and strong.

You now know what a compensator does in a pipeline. It helps keep your system safe and lets it last longer. Picking the right one stops leaks and saves money on repairs. It also helps you follow safety rules. The table below lists the long-term benefits you get:

| Benefit | Description |

|---|---|

| Enhanced System Reliability | Fewer failures and longer pipeline life |

| Reduced Repair Costs | Less money spent on fixing problems |

| Compliance with Regulations | Meets safety and building codes |

| Minimized Energy Loss | More efficient operation |

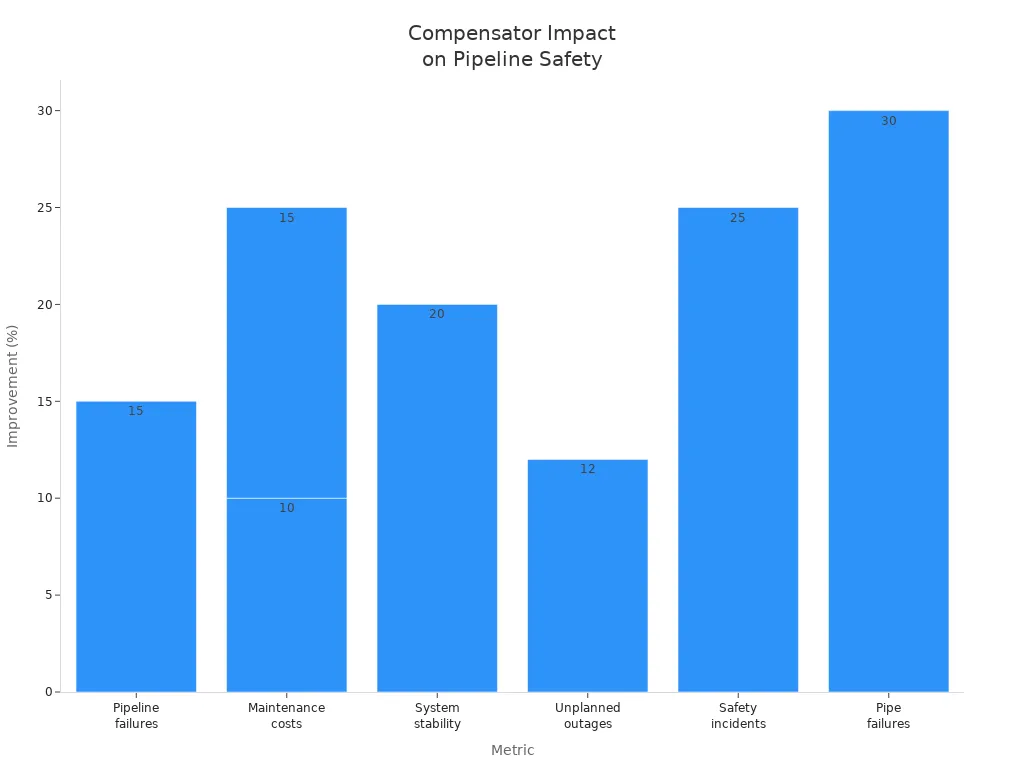

The chart below shows how a compensator makes pipelines safer and work better in many industries:

You can count on a compensator to keep your pipeline safe and working well.

FAQ

What does a compensator do in a pipeline?

You use a compensator to let the pipeline move safely. It absorbs changes from heat or pressure. This keeps the pipeline strong and helps prevent leaks.

How often should you check a compensator?

You should check your compensator every few months. Look for cracks or signs of wear. Regular checks help you find problems early.

Tip: Set a reminder to inspect your pipeline parts.

Can you install a compensator yourself?

You can install some types if you follow the instructions. For complex systems, you should ask a professional. Safety matters most.

What signs show a compensator needs replacing?

| Sign | What You See |

|---|---|

| Cracks | Lines or splits |

| Leaks | Wet spots or drips |

| Noise | Loud sounds |

If you see these, you should replace the part soon.