Most traffic cones weigh from 7 to 10 pounds. The weight depends on their size and what they are made of. The table below shows common sizes and weights for traffic cones. These cones are made from injection-molded plastic with recycled rubber bases:

| Cone Height | Base Size | Approximate Weight |

|---|---|---|

| 28 inches | 14″ x 14″ | 7 lbs |

| 28 inches | 14″ x 14″ | 10 lbs |

| 36 inches | 14″ x 14″ | 10 lbs |

Weight is important for how well traffic safety cones work:

- Heavier traffic cones stay in place better and do not tip over easily.

- Lighter safety cones are good for indoor or short-term use but may blow away in the wind.

Picking the right weight helps meet safety rules and makes sure cones work well in different places.

Hebei shangze is a supplier of all kinds of traffic cones, the material we can do :pvc, pe, rubber. The height of the cones we can do is 45cm 70cm, 90cm. reflective film we can do single film and double film, you can contact whatsapp 8618232902377, email: amelia@hb-shangze.com

Key Takeaways

- Traffic cones can weigh from 1 to 13 pounds. The weight depends on their size and what they are made of. Bigger cones are heavier and used outside. Heavier cones have wide, rubber bases. These cones do not fall over in wind or traffic. They are best for highways and busy roads. Lighter cones are easy to carry and move. They work well inside or in places with little wind. Warehouses and schools use these lighter cones. Reflective collars help cones be seen at night or in bad weather. This keeps drivers and workers safe. Always pick the right cone size and weight for where you use them. Follow local safety rules to stop accidents.

Traffic Cones Weight

Standard Weights

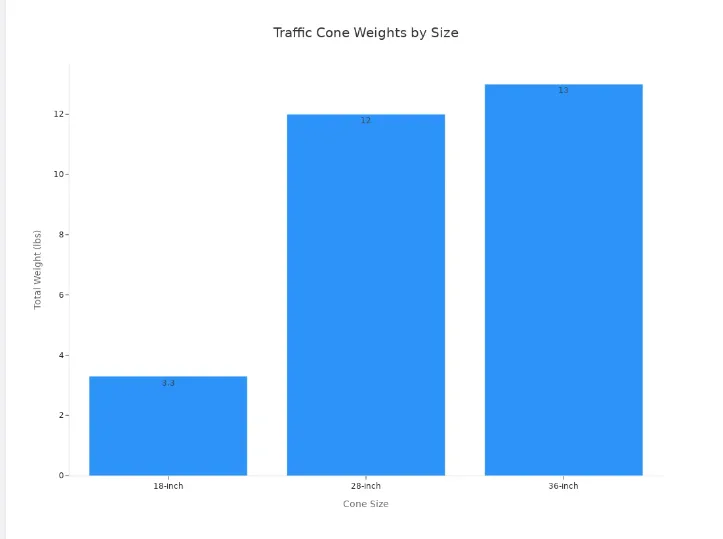

Traffic cones come in several sizes, and each size has its own typical weight. The weight depends on the height, base design, and material. Most 12-inch cones weigh between 2 to 3 pounds. These smaller cones work best indoors or in places with little wind. An 18-inch cone made from LDPE with a rubber base usually weighs about 3.3 pounds. The stem weighs around 1 pound, and the base adds about 2.3 pounds.

Larger cones, such as 28-inch and 36-inch models, have a higher weight range. A 28-inch cone with a rubber base can weigh from 7 to 13 pounds, depending on the base thickness. The 36-inch cones often weigh between 10 and 13 pounds. These heavier cones stay stable on highways and busy roads.

| Cone Size | Material | Base Material | Base Weight (lbs) | Total Weight (lbs) | Notes |

|---|---|---|---|---|---|

| 12-inch | PVC / Rubber / PE / LDPE | N/A | N/A | 2-3 | Best for indoor or light outdoor use |

| 18-inch | LDPE | Rubber | 2.3 | 3.3 | Stem 1 lb, base 2.3 lb |

| 28-inch | LDPE | Rubber | 5.5-12 | 11-13 | Weight varies with base thickness |

| 36-inch | LDPE | Rubber | 7-12 | 11-13 | Used for highways and busy roads |

Manufacturers use different methods to make cones. Injection-molded cones are heavier because they have a thick rubber base. Flow-molded cones are lighter and made in one piece. Rubber cones, made by extrusion, are the heaviest and most flexible.

Tip: Heavier cones with rubber bases work best for outdoor and highway use. Lighter cones are easier to move and stack but may tip over in strong winds.

Material Differences

The material used in traffic cones affects both weight and durability. PVC cones are lightweight and flexible. They resist impacts but can become brittle in very hot or cold weather. Rubber cones are heavier and absorb shocks well. They stay in place during storms or when cars pass by. LDPE and PE cones are also light, but their weight increases when paired with a rubber or PVC base.

| Material | Weight | Durability | Advantages | Disadvantages |

|---|---|---|---|---|

| PVC | Lightweight | Durable | Easy to move; flexible; impact resistant | Can get brittle in extreme weather |

| Rubber | Heavier | Very high | Stable in wind; absorbs shocks; good grip | Harder to carry; higher cost |

| Plastic | Lightweight | Moderate | UV resistant; easy to stack; low cost | Can crack in cold; less shock absorb |

The base material adds most of the weight. For example, a rubber base can make up 80% of the total weight of a cone. A 28-inch cone with a thick rubber base can weigh almost twice as much as one with a plastic base. The choice of material also affects how long the cone lasts. Rubber and HDPE cones last longer and handle rough use better than PVC or regular plastic cones.

There are many types of traffic cones, and each type uses different materials. The weight range for these cones depends on the combination of body and base materials. When choosing between different types of cones, people should consider where they will use them and how much stability they need.

Weight by Height

12-Inch to 18-Inch Cones

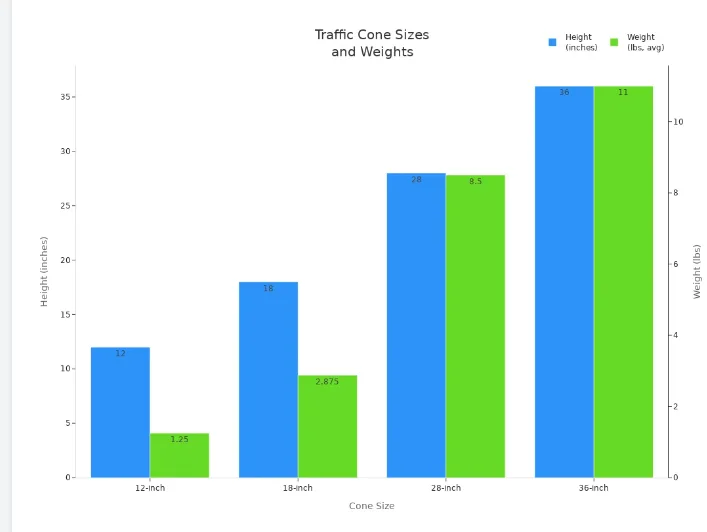

The weight and height of smaller traffic cones make them easy to move and store. These cones work best in places like warehouses, schools, or retail stores. The 12-inch cone usually weighs between 1 and 1.5 pounds. This size does not provide enough stability for road use. The 18-inch cone weighs from 2.75 to 3 pounds. People often use this size for small worksites or road closures in limited spaces. The 18-inch cone needs a 6-inch reflective collar for nighttime visibility.

| Cone Size | Weight Range | Typical Use | Additional Notes |

|---|---|---|---|

| 12-inch | 1 lb to 1.5 lb | Indoor or low-traffic areas | Not recommended for road use |

| 18-inch | 2.75 lb to 3 lb | Road closures, small worksites | Needs 6-inch reflective collar for night use |

The relationship between size and weight becomes clear in these smaller cones. As the height increases from 12 inches to 18 inches, the weight also increases. This extra weight helps the cone stay upright in light wind or when people walk by.

28-Inch to 36-Inch Cones

Larger traffic cones have a greater weight and height, which makes them suitable for outdoor and highway use. The 28-inch cone weighs about 7 pounds and has a base size of 14 by 14 inches. This cone works well in areas where cars drive up to 45 mph. The 36-inch cone weighs about 10 pounds and is best for highways or interstates where vehicles move faster than 45 mph.

| Cone Size | Typical Weight | Base Dimensions | Usage Recommendation |

|---|---|---|---|

| 28-inch | Approximately 7.0 lbs | 14″ x 14″ | Zones up to 45 mph |

| 36-inch | Approximately 10.0 lbs | 14″ x 14″ | Highways and interstates (over 45 mph) |

Base design and added weights play a big role in the stability of these cones. Many 28-inch and 36-inch traffic cones can use extra weights made from recycled rubber. These weights fit over the base and help prevent the cones from blowing over in strong winds. The added weight also keeps the cones steady when workers attach signs or lights. The size and shape of the base, along with the material, affect how well the cone stands up to harsh weather.

Note: Choosing the right weight and height for traffic cones helps keep roads safe and meets local rules.

Traffic Cone Specifications

Dimensions

Traffic cones come in different heights for safety. The most common sizes are 12-inch, 18-inch, 28-inch, and 36-inch. Each size is used for a different job. Some are for indoors, and some are for highways. The table below shows the main details for each cone size. It lists height, weight, where to use them, and if they need reflective collars.

| Cone Size | Height (inches/mm) | Weight (lbs) | Typical Use/Application | Reflective Collar Requirements |

|---|---|---|---|---|

| 12-inch | 12 in / 305 mm | 1 – 1.5 | Indoor or low-traffic areas (warehouses, schools) | Not recommended for road use |

| 18-inch | 18 in / 457 mm | 2.75 – 3 | Small-scale worksites, road closures, limited space areas | One 6-inch collar for nighttime |

| 28-inch | 28 in / 711 mm | 7 – 10 | Standard size for highways, roadwork, industrial settings | Two collars: 4-inch bottom, 6-inch top for nighttime |

| 36-inch | 36 in / 914 mm | 10 – 12 | Highway construction, large-scale road projects | Two collars: 4-inch bottom, 6-inch top for nighttime |

Wall thickness is also important for cones. Thicker walls make cones stronger and last longer. This extra thickness makes cones heavier. Makers try to keep cones strong but not too heavy. These choices help cones follow safety rules and work in many places.

Reflective collars help people see cones better. Most road cones need one or two reflective bands. These bands help drivers see cones at night or in bad weather. Many safety rules say cones must have these bands. Good visibility stops accidents and keeps workers safe.

Base and Stability

The base shape helps cones stay up in wind or when cars go by. Some features make cones more stable:

- Square bases spread out the weight and help cones stand on bumpy ground.

- Weighted bases make cones heavier, so they do not fall over easily.

- Rubber bases grip the road, even if it is wet or sloped.

- More weight at the base keeps cones from tipping in strong wind.

- Tests show square, heavy bases work best in windy or busy places.

The size and material of the base are very important. A bigger base helps cones stay up and be seen. The right base design helps cones meet safety rules. Reflective bands and good bases together make cones easier to see and help them pass checks.

Tip: Always look at the height, base size, wall thickness, and reflective collars before picking cones for a job. These things help cones be seen and stay in place.

Choosing the Right Weight

Usage Scenarios

Picking the right traffic cone weight depends on where you use it. Different places need different cones to keep people safe.

- Indoor places like gyms or warehouses do not have much wind. They also do not have a lot of cars or people moving fast. Lighter cones, such as 12-inch ones that weigh 1 to 1.5 pounds, are good for these spots.

- Outdoor places, like highways or construction sites, need heavier cones. These cones are 28 to 36 inches tall and weigh 7 to 12 pounds. They are easier to see and do not fall over easily.

- Wind is a big problem outside. Heavier cones with wide or weighted bases do not tip over in storms or when cars go by fast.

- Sometimes, workers need even more stability for events or roadwork. They can put extra weights on the base to help cones stay put.

- Bigger cones help drivers see danger from far away. This keeps everyone safer in busy or fast-moving areas.

People should always pick the right cone size and weight for the job. This makes sure cones stay where they should and help control traffic.

Regulations

Rules help people choose the right cone weight and size for each job. The Manual on Uniform Traffic Control Devices (MUTCD) gives rules for traffic cones in the United States. For example, MUTCD says cones on highways must be at least 28 inches tall. They also need reflective collars so drivers can see them at night. These cones must be heavy enough to stay up when wind or cars go by.

Local rules might also say what kind of cones to use in certain places. Some states have rules about the minimum weight for cones in road work or school zones. Following these rules helps keep everyone safe and makes sure you are doing things the right way.

Tip: Always check the rules before picking cones for any job. This helps keep workers and drivers safe.

Picking the right traffic cone weight and size keeps people safe and stops accidents.

- Heavy cones are good for windy places or busy roads. Light cones are better for inside or quiet areas.

- Using the right cone weight for the place helps workers stay safe and lets cars move easily.

- Accidents can happen if people do not follow the rules or use the wrong cone.Always look at local rules and product details before you buy cones. This makes sure you follow the rules and that cones can be seen.

FAQ

How does the weight of a traffic cone affect its use?

Heavier cones provide better control in windy areas. They stay upright when cars pass by. Lighter cones work well indoors or in places with little wind. The right weight helps keep the cone stable and safe.

Why do traffic cones need reflective collars?

Reflective collars help drivers see cones at night or in bad weather. These collars improve visibility and safety. Most road safety rules require cones to have reflective bands for proper traffic control.

Can you add extra weight to a traffic cone?

Yes, workers can add extra weight to the base for more control. This helps the cone stay in place during storms or heavy traffic. Extra weight also supports signs or lights attached to the cone.

What materials make cones most visible?

Cones with bright colors and reflective bands stand out best. The reflective material bounces light back to drivers. This feature helps with traffic control, especially at night or in low-light conditions.

Do all traffic cones meet the same safety standards?

Not all cones meet the same rules. Some need specific heights, weights, or reflective collars for certain jobs. Always check local laws and safety standards before using cones for traffic control.